solar lamp lights are often sold as simple, free-to-run, long-life outdoor solar lighting solutions. But in real residential, commercial, and municipal projects, many users face the opposite experience: lights dim after only a few weeks, batteries fail within months, sensors stop working, systems shut down during cloudy weather, and some units fail completely after the first rainy season. Why does this happen, and how can buyers avoid these problems? This guide explains the real engineering reasons behind solar-light failure, shows the weakest parts inside a solar system, and gives procurement rules that help you choose products that last 5–10 years instead of only a few months.

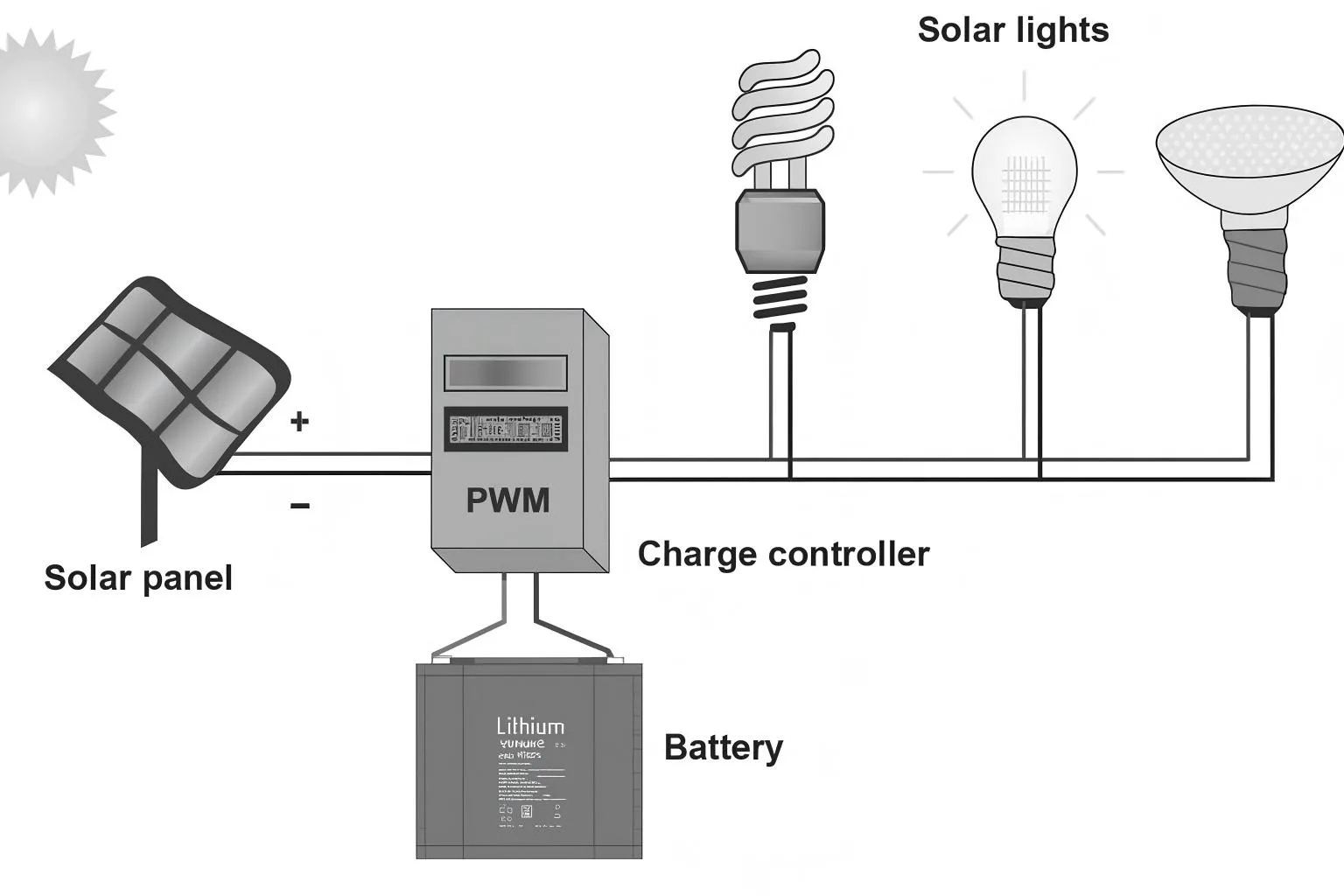

How solar lamp lights Actually Work (System-Level Overview)

Before understanding why failures occur, it’s important to understand how a solar light is engineered.

The Four Components That Determine Lifespan

Before understanding why solar lights fail, it’s important to know how a solar lighting for outdoors system is built. Every solar energy street light depends on four core components, and the full system will stop working if any one of them fails.

PV street lamp solar panel— power source

The street light solar panelcollects sunlight and produces electricity. Certified panels under IEC 61215 / 61730typically lose only 0.5–1% output per year, but low-quality panels degrade much faster, reducing the energy available at night.

Solar powered light batteries— energy storage

The battery stores the daytime energy for use after sunset. It is also the most common failure point.

• Quality LiFePO₄ batteries (IEC 61427) provide 2,000–4,000 cycles.

• Cheap batteries may last only 300–500 cycles, causing dimming or early shutdown.

Solar Controller — energy manager

The controller regulates charging, discharging, and the light sensor. Industry data and MPPT/PWM studies show that controllers are one of the most failure-prone partsdue to heat, moisture, and overload.

LED Module — light output

The LED converts stored energy into visible light. Based on LM-80 and TM-21data from major brands (Cree, Nichia, Lumileds), LEDs typically last 50,000–100,000 hoursand rarely fail suddenly.

Because the PV panel, battery, controller, and LED module work as a chain, the system fails when the weakest link fails.

Many municipal buyers assume “the LED is broken,” but field data from SEPA and global testing labs show that over 90% of solar-light failures come from the energy chain—especially the battery and controller—not from the LED itself.

The Real Reasons Solar Lights Stop Working Quickly

Based on an analysis of several top global solar-lighting manufacturers and real-world field data, all common failures can be grouped into six major categories.

The solar street light panel Cannot Charge Properly (Dust, Shading, Weather)

Why Charging Fails

Solar charge lamp often fail because the system cannot collect enough energy during the day. Several well-documented factors reduce charging performance:

Dust, pollution, pollen, and bird droppingsblock sunlight and can cut panel output by 25–40%(NREL).

Shading from trees or buildings, even for 2–5 hours, can drop total energy production by 30–40% (Fraunhofer ISE).

Vertical or incorrect mounting angles reduce irradiance by 20–40% compared with optimal tilt (Sandia Labs).

Long periods of clouds or rain prevent the battery from charging fully.

Wrong orientation—not facing the sun—reduces annual energy by 10–20% (IEC 61853).

Engineering Impact

Even 10% shading on a PV module can reduce output by 34–38%, because one shaded cell affects the entire string. When charging is insufficient:

- the solar lights rechargeable batteriesnever reaches full capacity

- Thesolar lamp led enters early dim mode

- runtime gets shorter each night

- eventually the system shuts down completely

- This is the most common failure pattern in low-cost solar lighting.

B2B Takeaway

To avoid early failures in solar lighting projects, choose systems built with the right charging components and installation practices:

- Use monocrystalline solar panels with at least 22% efficiencyto maintain strong energy collection even in low-irradiance conditions.

- Select solar panels for the roadwith hydrophobic or self-cleaning glass coatings (optional) to reduce power losses caused by dust and pollution buildup.

- Ensure proper pole height and site placementso the PV panel stays free from shading during peak sun hours.

Following these specifications keeps the led solar panel performing at full capacity, ensures stable daily charging, and delivers reliable night-time operation throughout the system’s lifetime.

Battery Aging Is Faster Than Expected

A solar lamp with battery can only perform well if the battery is strong. Industry studies from NREL, SEPA, and SolarAid all show the same pattern: 60–80% of solar-light failures come from battery problems—not from the LED.

Common Problems

Batteries for solar street lights fail early when low-quality lithium or NiMH cells are used, when the battery capacity is too small, or when the system is forced into deep charge/discharge cycles every night. High ambient heat also speeds up chemical aging. Research from NREL and DOE shows that temperatures above 45°C can make batteries lose capacity 2–4 times faster.

Why Batteries Die Early

Solar batteries work poorly in harsh environments. Extreme heat, high humidity, daily deep discharge, or overcharging from a cheap controller or an ineffective battery charger for solar light batteries will damage the cells. Low-cost products often rely on recycled 18650 cells, small 1500–2000 mAh capacities, and no temperature protection. These batteries typically last only 150–300 cycles, which equals about 6–12 months outdoors.

B2B Takeaway

For reliable long-term performance, procurement teams should specify:

- LiFePO₄ batteries rated for 2000–4000 cycles

- ≥6000 mAh capacityfor small solar units, ≥12Ah for solar street lights

- A temperature-controlled BMSfor safe charging and protection

- A minimum 2–3 year battery warranty

These requirements match global solar-lighting standards and ensure the system can survive real outdoor conditions for years—not months.

Water Ingress & Moisture Destroy Components (IP Rating Problems)

Many low-cost led solar flood lights claim “IP65 waterproof,” but their real waterproof performance often does not meet IEC 60529 standards. When sealing materials, gaskets, or structural joints are poorly designed, moisture can enter the housing. This leads to visible warning signs such as condensation inside the lens, rust on terminals, corrosion on the PCB, or water buildup inside the battery compartment. These issues are well-documented in public lighting failure reports and occur most often in rainy, humid, or coastal environments, where strong waterproofing and anti-corrosion measures are essential.

Once moisture reaches internal components, the risk of damage increases sharply. street lighting luminaire controllers may short-circuit, led lights that flicker, and batteries can degrade faster due to corrosion or temperature stress. Sensors may also stop detecting daylight correctly. While the exact failure rate varies by product quality, moisture ingress is one of the most common reasons for outdoor solar-lighting breakdowns.

B2B Takeaway

For long-term reliability, buyers should require:

✔ Minimum IP66 enclosure, tested under IEC 60529

✔ Silicone sealing instead of foam tape, which absorbs moisture

✔ Gasket-protected battery housing to prevent internal condensation

✔ Salt-spray testing (recommended for coastal or high-humidity regions)

These specifications help ensure that a solar light can withstand harsh outdoor environments and maintain stable performance over many years.

Light Sensors or Controllers Malfunction

Why the Controller Is the Real Brain of a Solar Lighting System

Across field studies and industry evaluations, the street lighting solar controller—not the LED—is confirmed as the most failure-prone and most important part of a solar powered light system. LED modules rarely fail because LM-80/TM-21 testing gives them lifetimes of 50,000–100,000 hours. In contrast, the controller manages the full energy chain: charging, discharging, sensing daylight, and protecting the battery. When it fails, the entire system shuts down.

Common Controller Failures

Daylight sensor errors

Photocells for lights often misread light levels due to dust, yellowing, humidity, or IC aging. This leads to solar lamps staying ON during the day or OFF at night—an issue frequently seen in low-cost motion sensor lights solar outdoor products.

IC and MOSFET failures in heat or humidity

Low-cost controllers use components that degrade quickly above 60°C or in high-moisture conditions, causing unstable operation or complete shutdown.

Firmware or control-logic faults

Poorly designed algorithms can produce flicker, early shut-off, or incorrect dimming due to inaccurate voltage detection or timing errors.

Battery damage from improper charging

Without proper protection, cheap controllers can overcharge or over-discharge the battery, reducing lifespan and triggering early system failure.

B2B Procurement Requirements

To avoid controller-related failures, specify:

- Smart MPPT or high-quality PWM controller

Ensures stable charging efficiency and improved runtime. - Anti-UV photocell outdoor light

Maintains correct dusk/dawn detection under long-term sun exposure. - Calibrated dusk/dawn threshold (±10–30 lux)

Prevents false ON/OFF switching and saves stored energy. - Surge protection ≥ 2.5 kV

Protects the system from lightning, grid disturbances, and electrical spikes.

These requirements ensure stable long-term performance, protect the battery, and reduce the risk of unexpected field failures.

LED Module Isn’t the Problem—but Heat Can Kill It

LED chips are highly reliable and almost never fail on their own. Their long life—often 50,000 to 100,000 hours—is well supported by LM-80 and TM-21 test data. However, this performance depends on one critical factor: temperature. If the heat sink is poorly designed, the LED junction temperature climbs, light output drops, and the expected lifespan can shrink from more than 50,000 hours to less than 10,000 hours.

Common thermal triggers include sealed housings with no airflow, plastic heat sinks that cannot conduct heat, and drivers packed into small enclosures where temperatures rise quickly. These conditions force the LED to run hot, accelerating lumen depreciation and causing early system failure.

B2B Takeaway:

To avoid thermal failures, specify:

- ADC12 die-cast aluminum heat sinksfor proper thermal conduction

- Thermal pads and heat-conduction channelsto move heat away from the LED

- LED junction temperature ≤ 85°C, the industry standard for long-term stability

Well-engineered thermal control protects lumen output, extends system life, and ensures reliable outdoor performance.

Wrong Installation Environment or User Behavior

Even well-built solar lamps outdoor can fail if they are installed in the wrong place or at the wrong angle.Real-world studies from NREL, Fraunhofer ISE, NASA, and Lighting Global show that several site factors can cut system performance by 30–40% or cause full shutdown.

Common installation risks include:

Shaded locations

Even 10% shading can reduce solar charging by 30–40%. Courtyards with trees, walls, or nearby buildings often block sunlight for several hours each day.

Low-sunlight regions (<3 peak sun hours/day)

Areas with less than 3 PSH cannot fully charge a solar battery. The light slowly enters dim mode and eventually shuts down.

Nearby bright street lights (sensor confusion)

Strong external lighting can fool the photocells for outdoor lights, causing the lamp to turn off at night or stay on during the day.

Incorrect tilt angle (<10°)

Panels mounted too flat may collect water, dirt, or snow, leading to corrosion and poor charging. Most solar standards recommend at least a 10° tilt.

Wrong orientation

In the northern hemisphere, a north-facing panel can lose 20–40% of its solar input. Panels must face south for maximum charging.

B2B Takeaway:

To avoid site-related failures, a professional supplier should always provide:

A full site assessment:Solar-radiation analysis based on NASA/PVGIS data

A clear installation guide:Recommended tilt angle and orientation for the location

These steps ensure the lamp solar system gets enough sunlight and performs reliably for many years.

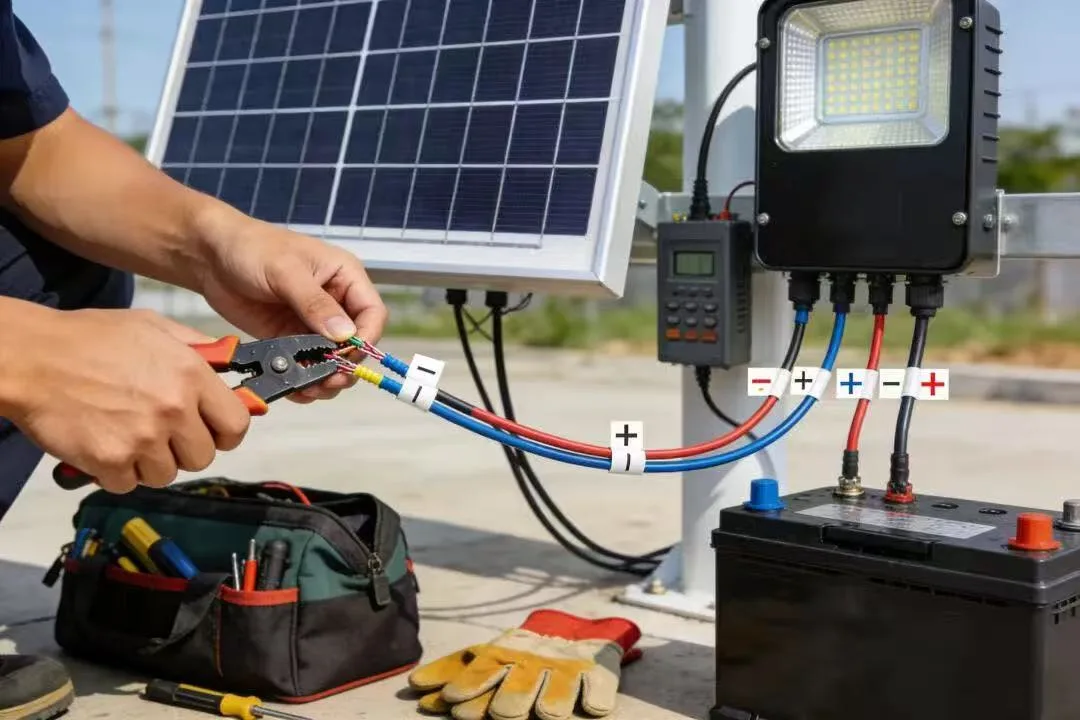

How to Troubleshoot Solar Lights Quickly

Use this standardized checklist followed by OEM manufacturers when diagnosing solar-light failures.

First, clean the lamp post solar panel and remove any dust, bird droppings, or leaves that may block sunlight. Then reset the compact street lighting controller by switching it OFF and ON, or covering the panel to check whether dusk mode activates correctly. Next, test the battery voltage—LiFePO₄ batteries should read between 3.2V and 3.4V per cell. After that, inspect all internal wiring and connectors for rust, loose joints, or signs of moisture. Finally, check the LED module by powering it directly with DC input; a healthy module should still light normally.

This simple workflow helps identify whether the issue comes from the panel, controller, battery, wiring, or LED module.

How to Extend the Lifespan of Solar Lights

Set up a simple maintenance plan to keep solar lights reliable. Every 2–3 months, clean the PV panel, check the battery compartment, inspect seals and gaskets for damage, verify that the sensor is working accurately, and tighten all mounting brackets. In addition to routine checks, replace key components on a fixed schedule: standard batteries every 2–3 years (LiFePO₄ packs every 4–6 years), controllers every 3–5 years, and PV panels roughly every 8–12 years. This combination of regular inspection and planned replacement prevents sudden failures and keeps the system performing close to its original design.

Procurement Criteria: How to Buy Solar Lights That Don’t Fail

Choosing a solar light post lamp that lasts 5–10 years depends on engineering quality, not price. The following criteria—based on IEC, Lighting Global, NREL, Fraunhofer, and leading manufacturers—should guide all professional procurement and technical specifications.

Solar Panel Requirements

High-efficiency PV panels are the core energy source of any solar power lighting system.

Specify: monocrystalline panels ≥21–22% efficiency, 3.2 mm tempered glass, anti-reflective or hydrophobic coating, and IEC 61215/61730 certification. because PV wattage must match battery capacity and work effectively as the primary charger for solar light batteries.If the PV panel is undersized, the battery cannot fully charge—causing dimming, reduced runtime, and early shutdown.

Battery System Requirements

The battery is the most common failure point in solar lighting.

Specify: LiFePO₄ chemistry (2000–4000 cycles), ≥6000 mAh for garden lights or ≥12–24Ah for street lights, A-grade cells with full BMS protection, and UN38.3 compliance.

Low-grade batteries often last only 150–300 cycles, leading to early dimming and system failure within 6–12 months.

Controller Requirements

The controller manages charging, discharging, lighting logic, and system protection.

Specify: MPPT controllers (10–30% higher efficiency), calibrated photocells (±10–30 lux), ≥2.5 kV surge protection, adaptive dimming, and UV-resistant sensor windows.

Controller malfunction accounts for 30–40% of field failures, making it the second-most critical component after the battery.

LED Module Requirements

LED chips rarely fail, but their performance affects brightness, efficiency, and long-term output.

Specify: LM-80 tested LEDs, L70 ≥50,000 hours (L90 ≥30,000 preferred), 160–180 lm/W system efficacy, SDCM ≤5, and roadway optics Type II–V.

High-efficiency LEDs reduce load on the battery and PV system, extending overall system lifespan.

Environmental & Mechanical Requirements

Solar lights for outdoor must withstand rain, humidity, corrosion, and physical impact.

Specify: IP66/IP67 ingress protection, IK08/IK10 impact rating, ADC12 die-cast aluminum housing, ≥72-hour salt-spray resistance, and UV-stable PC lenses.

Waterproofing failure ranks among the top five root causes of premature solar light failure, especially in coastal or tropical climates.

Installation & System Design Requirements

Correct installation is as important as good components.

Specify: tilt angle ≥10–15°, correct orientation (true south/north), zero shading, proper pole height and spacing, and PSH ≥4–5 hours.

Incorrect tilt, poor solar exposure, or wrong mounting can cause any brand of solar lighting to fail within months.

Minimum Warranty Requirements

Warranties should reflect the expected lifecycle of each subsystem.

Specify: 3–5 years full system warranty, 2–3 years battery warranty (LiFePO₄ up to 4–6 years), 3+ years controller warranty, and 5 years LED module warranty.

Different components age differently, so segmented warranties ensure proper long-term protection.A durable solar street light depends on engineering—not marketing claims.By evaluating PV efficiency, battery chemistry, controller design, LED performance, waterproofing, and installation conditions together, professional buyers can ensure stable 5–10 year operation, even in harsh environments.

Conclusion: Solar Lights Don’t Fail Without a Reason—They Fail When the System Is Weak

In nearly all real-world cases, out door solar lights fail early because they don’t charge enough, use low-grade batteries, have weak waterproofing, rely on poor controllers, or are installed incorrectly. But when a system is engineered properly—with high-efficiency PV panels, LiFePO₄ batteries, IP66-rated protection, and smart, stable controllers—it can run reliably for 5–10 years, even in harsh environments. For professional buyers, long-term success comes from choosing the right components and engineering—not simply choosing the lowest price.