Introduction

Light poles are important for luminaire outdoor led lighting. They provide support for lights in parking lots, streets, parks, and commercial areas. Many property managers, contractors, and building owners don’t pay attention to their parts until something goes wrong, like storm damage or loose fixtures. If you are in charge of putting up or fixing street pole lights, especially in busy areas, it’s important to understand the main lamp pole parts. This knowledge can help keep things safe, lower lamp post repair costs, and help you pick the right pole. In this guide, we’ll explain each part, what it’s made of, and answer common questions like “Why is a handhole important?” and “How do anchore bolts stop the pole from tipping?” By the end, you will be ready to make good decisions about your outdoor lighting.

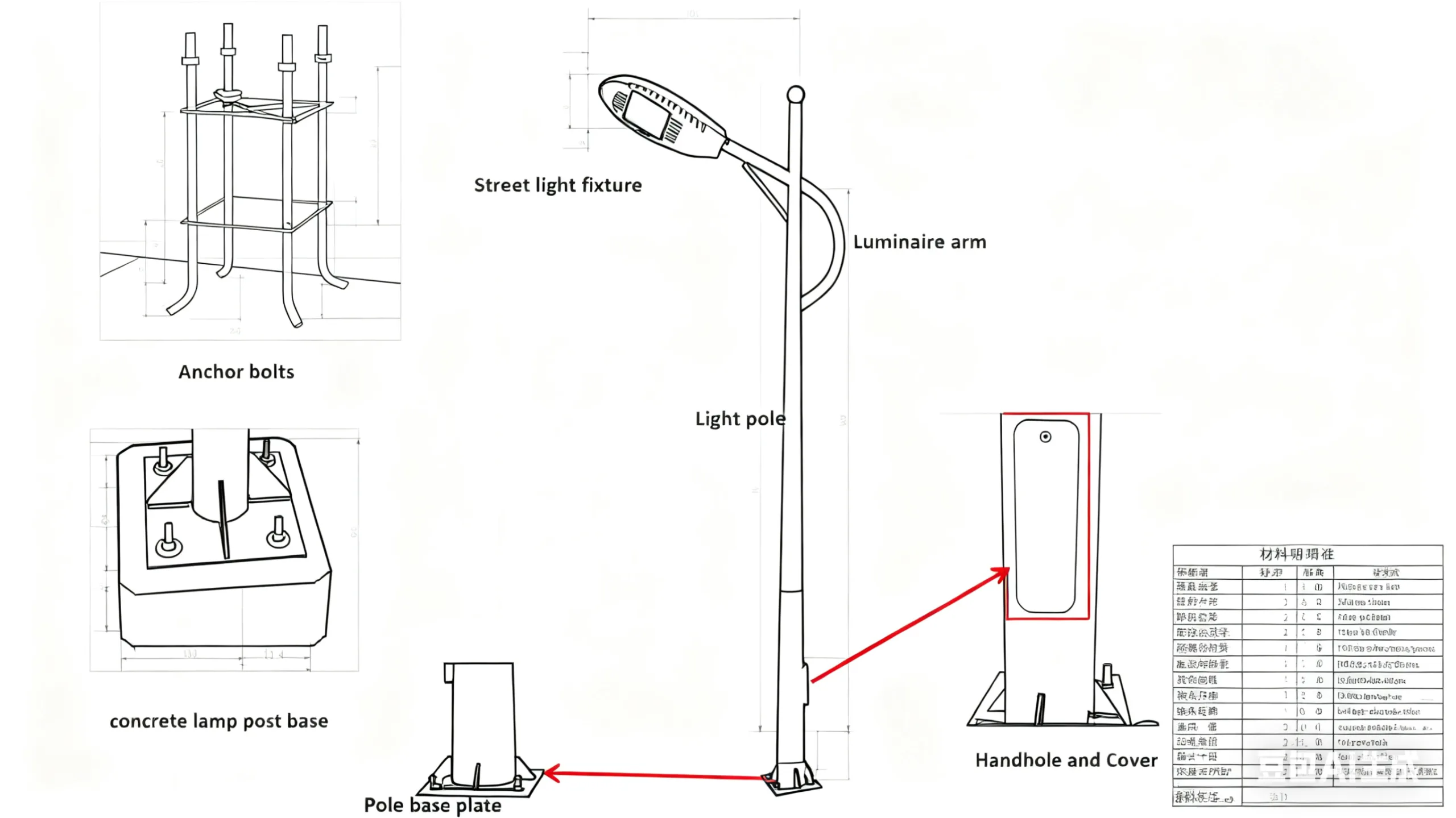

The 6 Core Components of a Light Pole

Every standard light pole—whether for a parking lot, street, or park—relies on six key parts to function. These components work together to provide stability, protect wiring, and support the fixture. Here’s a breakdown of each component, including its function, materials, and key considerations.

Every standard a light pole—whether for a parking lot, street, or park—has six important light post parts. These parts work together to keep the pole stable, protect the wires, and hold the light. Here is a breakdown of each part, including what it does, what it’s made of, and key things to consider.

Base plate for pole: The Foundation of Stability

The base plate (also called a “pole base” or “mounting plate”) connects the pole lights to the concrete foundation. Think of it as the “feet” of the pole—it distributes the weight of the pole and fixture, as well as external forces like wind, preventing the pole from tilting or sinking.

Key Functions of a Base Plate

Weight Distribution: The base plate spreads the weight of the pole and fixture over a larger area (typically 12–24 inches in diameter for light poles commercial), preventing damage to the foundation.

Secure Mounting: The pre-drilled holes in the base plate for light fixture align with anchoring bolts (see Section 2.5) to create a stable connection.The size and hole positions of the base plate must match the embedded bolts to avoid installation issues.

Base plate Thickness and Stability:The thickness of the flange directly affects the stability of the light pole. If the flange is too thin, it may bend over time, causing the pole to tilt or even fall, which can be unsafe.

Leveling: Contractors use the base plate to ensure the pole is perfectly vertical during outdoor lamp post installation. Small adjustments (e.g., adding shims) prevent leaning and fixture misalignment.

Materials Used for Base Plates

Hot-dip Galvanized Steel: It’s strong, rust-resistant, and affordable. It works well in most outdoor areas, especially wet climates.

Stainless Steel: Used in coastal areas or places with saltwater, because it resists rust better than galvanized steel.

Aluminum: Rarely used for base plates because it’s not as strong as steel. It can be used in homes or light applications but is not good for commercial or windy areas.

Shaft: The”Backbone” of the Light Pole

The shaft (or “pole body”) is the long, vertical tube that connects the base plate to the lamp post cross arm or fixture. It’s the most visible part of the light pole, but its importance goes beyond aesthetics—it houses electrical wiring, supports the fixture’s weight, and must withstand environmental stressors like wind, ice, and temperature changes.

Key Functions of a Shaft

Structural Support: The shaft bears the full weight of the lamp arm and fixture. For high mast lamp pole (e.g., 40-ft poles in large led lighting for parking lots), the shaft must be strong enough to prevent bending or excessive swaying in the wind.

Electrical Protection: Most shafts are hollow, allowing electrical wires to run from the base to the fixture, protecting them from rain, snow, and pests (like rodents that might chew through exposed wires).

Weather Resistance: The shaft is exposed to the elements 24/7, so it must resist rust, corrosion, and UV damage. A damaged shaft can lead to water infiltration, damaging wires, or structural failure, increasing the risk of the street lamp poles falling.

Materials Used for Shafts

The material affects the shaft’s strength, durability, and cost. Common materials include:

| Material | Best For | Pros | Cons |

| Hot-dip Galvanized Steel | Commercial parking lots, streets, high-wind areas | Strong, corrosion-resistant (zinc coating), affordable | Heavier than aluminum, may corrode in saltwater |

| Aluminum | Residential areas, coastal regions | Lightweight, rust-proof, low maintenance, sleek appearance | Less strong than steel, more expensive |

| Fiberglass (FRP) | Wet environments (e.g., parks near lakes) | Non-conductive, lightweight, resistant to chemicals and salt | Less strong than steel, cracks in extreme cold, more expensive |

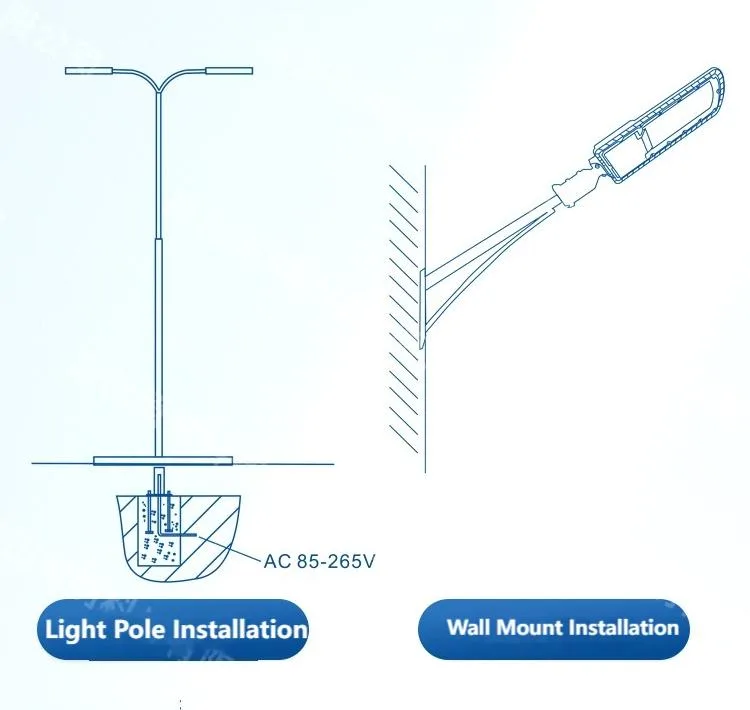

Lamp Arm: The “Arm” That Holds the Fixture

The lamp arm (or “fixture arm”) is the horizontal or angled piece extending from the top of the shaft to hold the led lighting fixtures. While not all streetlight poles have a lamp arm (e.g., “direct-mount” poles attach the fixture directly to the shaft), they are common in parking lots, streets, and parks where precise positioning of fixtures is required.

Key Functions of a Lamp Arm

Fixture Positioning: The lamp arm positions the ligth fixture away from the shaft, ensuring light covers the intended area. For example, a 2-ft arm in a parking lot ensures the fixture is centered over a parking space, avoiding shadows from the light pole light fixtures.

Weight Support: The lamp arm supports the weight of the fixture (typically 10–50 lbs for parking lot lighting fixtures) and must resist torque. In windy conditions, the fixture can twist the arm, so it needs to be strong enough to withstand the force.

Aesthetic and Functional Design: Lamp arms can be straight, curved, or decorative (e.g., decorative pole lighting for historic districts). Some designs include holes for wiring or brackets to adjust the fixture’s angle.

Materials Used for Lamp Arms

Lamp arms are usually made from the same material as the shaft to keep them matching in strength and appearance:

Steel: Used for heavy fixtures or windy areas. Hot-dip galvanized steel resists rust and holds more weight.

Aluminum: Used for lightweight fixtures or coastal areas. Aluminum arms are rust-proof and adjustable.

Fiberglass: Used for non-conductive areas (like near power lines) or places with strong corrosion.

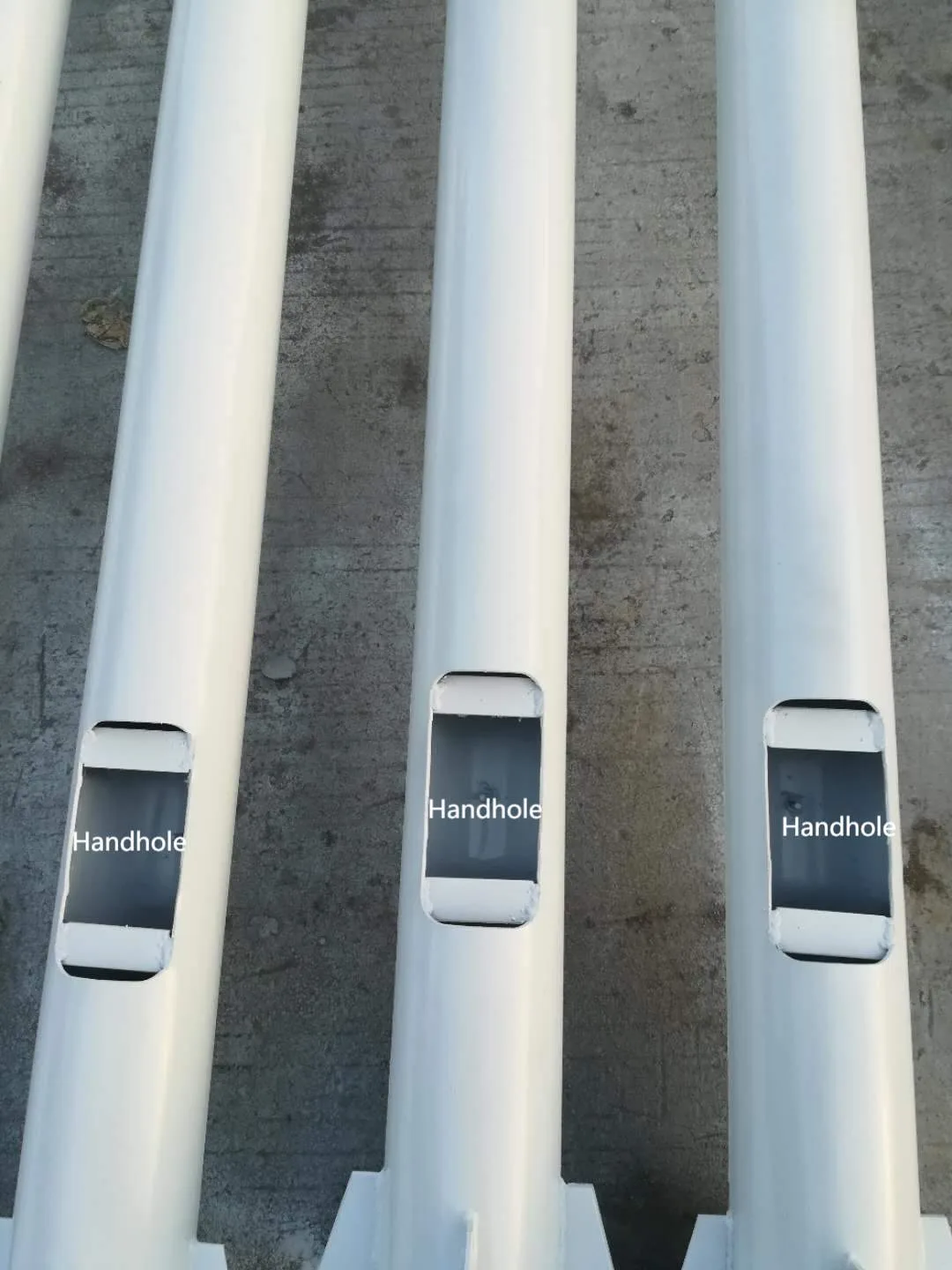

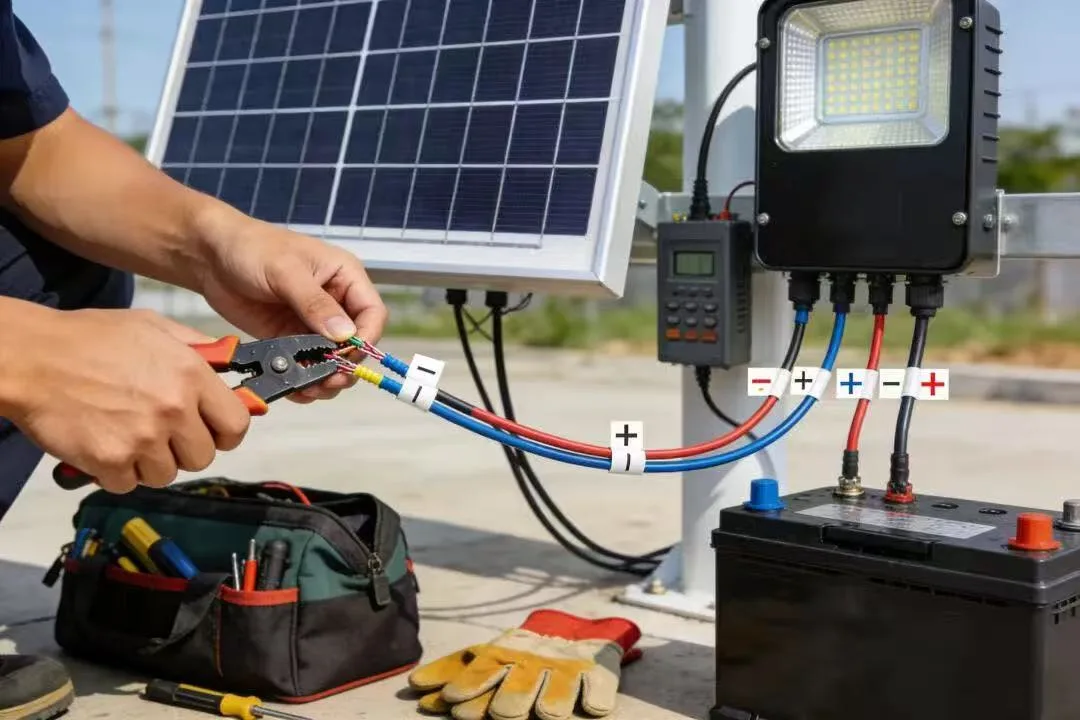

Handhole: The “Door” for Maintenance

The handhole (also called a “service hole” or “access hole”) is a small opening, typically 6–12 inches above the base plate, that provides access to the pole’s internal wiring and electrical components. Though often overlooked, it is essential for maintenance and repairs.

Key Functions of a Handhole

Electrical Access: Electricians use the handhole to connect or repair wires (e.g., replacing a faulty ballast or wiring a new fixture), avoiding the need to cut into the shaft, which could damage its structure.

Inspection: Maintenance teams use the handhole to check for issues such as water infiltration (e.g., rust) or pest infestations (e.g., rodents nesting in the wiring).

Future Modifications: The handhole allows electricians to run new wires for future upgrades, like adding motion sensors or smart lighting controls, without major modifications.

Design and Location Considerations

Size: Handholes are usually 4×6 inches or 6×8 inches, large enough to fit a hand but small enough to maintain shaft strength. Larger poles (30+ ft) may have two handholes for easier access.

Location: Handholes are typically placed 6–12 inches above the base plate to avoid standing water. In areas with heavy snow, they may be placed higher (18–24 inches) to prevent snow blockage.

Smooth Edges: The edges are rounded or covered with a rubber gasket to prevent injury when accessing the wiring.

Anchors bolts: The “Anchors” That Keep Poles Grounded

The anchor bolts (or “foundation bolts”) are long, threaded metal rods that secure the base plate to the concrete foundation. Embedded in the concrete during installation, they keep the pole grounded, even during strong winds or earthquakes.

Key Functions of Anchor Bolts

Structural Stability: Anchor bolts for light pole hold the pole in place by resisting forces from wind or earthquakes. They keep the base plate down, stopping the pole from tipping or sliding off the foundation.

Secure Connection: Unlike screws or nails, light pole anchor bolts are made to handle heavy loads. They are tightened to a specific level to keep the pole firmly attached to the foundation.

Long-Term Durability: Made from materials that resist rust, anchor bolts stay strong over time, keeping the pole stable.

Materials and Sizing

Materials: Most anchor bolts are made of hot-dip galvanized steel (general use) or stainless steel (for coastal or corrosive environments). High-wind areas may use high-strength steel (grade 8.8 or 10.9) for extra durability.

Sizing: The size depends on the pole height and weight. A 20-ft steel street light pole typically uses ?-inch diameter bolts (6–8 inches long). Taller poles (30+ ft) require 3/4 anchor bolts (?-inch diameter, 10–12 inches long). Most poles use 4 or 6 bolts, spaced evenly around the base plate.

Installation Tips for Anchor Bolts

Embedment Depth: Anchor bolts should be embedded at least 10 times the bolt diameter (e.g., ?-inch bolt needs 5 inches of embedment). Shallow embedment risks the bolt pulling out.

Alignment: During pouring, ensure anchor bolts align with the base plate’s pre-drilled holes. Misalignment makes attaching the base plate properly impossible, causing a tilted pole.

Torqueing: After attaching the base plate, tighten bolts to the manufacturer’s recommended torque (e.g., 30 ft-lbs for ?-inch bolts). Over-tightening can strip threads; under-tightening leaves the pole loose.

Hand Hole Cover: The “Seal” for Maintenance Access

The hand hole cover is a protective seal used to close the hand hole on the light pole shaft. Typically made from metal or plastic, it is designed to withstand outdoor conditions and prevent unauthorized access to the interior of the pole. The cover is easily removable for maintenance or inspection.

Key Functions of hand hole covers

Protection: The handhole cover keeps out debris, water, and pests, protecting the wires and electrical parts inside the pole from damage.

Security: It keeps the handhole closed, stopping people from opening it and tampering with the electrical parts.

Ease of Maintenance: The hand hole cover plate can be removed easily, allowing workers to access the wires for repairs or upgrades.

Materials and Design

Materials: Street light hand hole covers are usually made of metal (like galvanized steel) or plastic (like PVC or high-density polyethylene) to resist weather and last longer.

Design: The hand hole covers for light poles typically has a simple lock or screws for easy removal and reattachment. Some covers have rubber seals to keep out water.

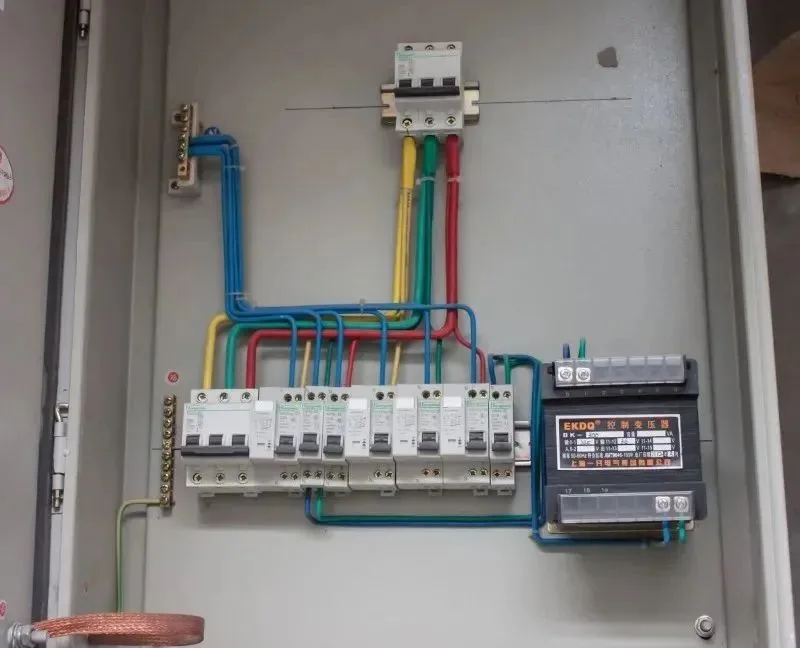

Access Door: The “Doorway” to Internal Components

An access door is a larger opening located at the bottom of the shaft, designed to allow maintenance personnel easier access to the interior of the light pole. These doors are typically locked or latched to prevent unauthorized entry.

Key Functions of Access Door

Easy Access: The access door gives maintenance workers a large opening to reach the electrical parts and wiring inside the pole. This is helpful for poles lights with more complex systems that need regular servicing.

Security: Access doors have locks or latches to keep them secure, stopping tampering, vandalism, or unauthorized changes to the internal parts.

Versatility: Access doors allow for the installation of larger parts, like control panels or batteries, and can be used for upgrades without replacing the whole pole.

Materials and Design

Materials: Access doors are usually made from metal (like galvanized steel or aluminum) for strength and to resist rust.

Design: The doors have locks for security and are often hinged for easy opening. They are usually sealed with rubber gaskets to keep moisture and dirt out.

FAQ

1.What size base plate do I need?

The size depends on the height pole and weight. For a 20-ft pole with a 30-lb fixture, a 16×16-inch base plate is typical. Taller poles (30+ ft) require larger plates (24×24 inches or more). Always check the manufacturer’s specifications for the recommended size.

2.Can I reuse a base plate when replacing the pole?

Only if it’s in good condition (no rust, cracks, or bent holes) and compatible with the new pole. Incompatible base plates can cause instability.

3.Why do some shafts have a tapered design (wider at the base, narrower at the top)?

Tapered shafts are designed for strength and stability. The wider base distributes weight to the base plate, while the narrower top reduces wind resistance, which is critical for tall poles. This design also uses less material, making the pole lighter without sacrificing durability.

4.How thick should a shaft be?

The thickness (called “gauge”) depends on pole height and material. For a 20-ft steel pole, an 11-gauge shaft (about 0.120 inches thick) is typical. Taller poles (30+ ft) require thicker gauges (e.g., 7-gauge, 0.180 inches) for added support and wind resistance. Aluminum shafts are usually thicker (e.g., 0.25 inches) to compensate for their lower strength.

5.How long should a lamp arm be?

It depends on the lighting goal. A 1.5–3-ft arm is common for parking lot poles, positioning the fixture over a parking space without excessive sway. For street poles, arms may range from 4–6 ft to cover both sides of the sidewalk. Match the arm length to the fixture’s beam angle to avoid overlighting adjacent areas

6.Can I add a lamp arm to an existing pole?

Yes, if the pole is designed for it. Many poles have pre-drilled holes at the top for attaching arms. Ensure the pole can support the added weight (arm + fixture) and that the arm is compatible with the pole’s material (e.g., an aluminum arm for an aluminum pole).

7.What if the handhole is too small for my needs?

Choose a pole with a larger handhole (e.g., 6×8 inches) or request a custom size from the manufacturer. Avoid widening an existing handhole, as it can weaken the shaft.

8.Can a handhole leak?

Yes, if the cover is missing, damaged, or improperly sealed. Leaks can cause water damage or rust inside the shaft. Inspect and replace handhole covers regularly if cracked or corroded.

Conclusion The Essential Components of a Light Pole

Light poles are made up of several critical components that work together to support and illuminate outdoor spaces. Understanding the functions of the base plate, shaft, lamp arm, hand hole, anchor bolts, hand hole covers, and access doors is crucial for designers, engineers, and maintenance personnel. Proper selection, installation, and maintenance of these components ensure the safety, stability, and functionality of light poles, particularly in urban environments where they must withstand varying environmental conditions.