Introduction to Standard-Height street lamp poles

Choosing the right street light pole height is important for safety, good lighting, and project approval. Usual height ranges give a guide for houses, business areas, and city roads. But the final choice also depends on three things: optical (light spread, even light, glare control), structural (wind rating, pole strength, foundation safety), and electrical (insulation, protection, and power type like AC, DC, or solar). The design must also follow rules such as EN/IEC 60598-2-3, EN 13201, and ANSI C136, and pass CE and UL tests so the product can be used in many regions.

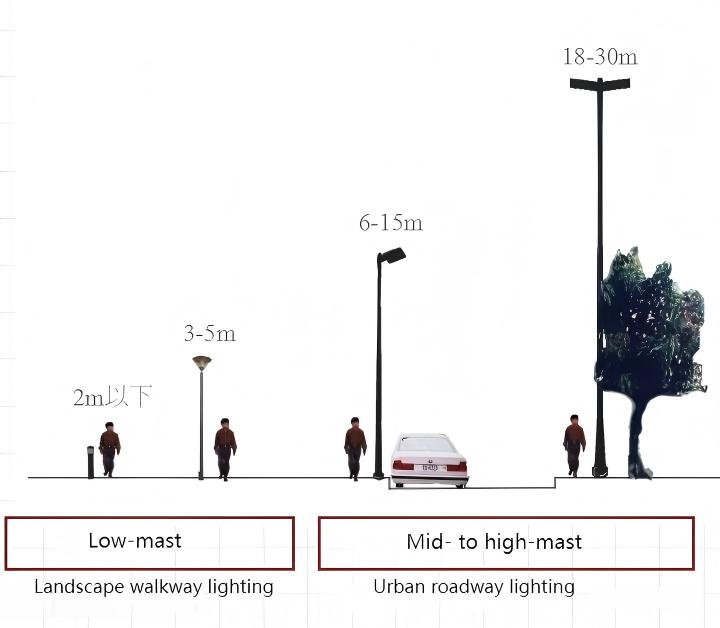

Standard Heights and Application Scenarios

Streetlight pole heights are usually 6 m, 8 m, 10 m, 12 m, or 15 m. The choice depends on factors like road width and distance between pole street lights. If the wrong height is used, it may cause glare and uneven lighting, which can affect drivers and pedestrians. To avoid this,light pole on street height design should follow a standard approach, finding balance between lighting efficiency, environmental fit, and safety, and setting the right range for each use case. This section will look at the rules, design logic, and how they are applied in residential areas, business zones, and city infrastructure.

Residential Areas: Balance of Safety and Comfort

Driveway lighting: Use taller poles, 4 -6 m high, with spacing of 12 -18 m, adjusted as needed. This gives drivers clear vision, avoids glare, and reduces disturbance to residents.

Pathway lighting: Use shorter poles, 2 -3 m high, with spacing of 5 -10 m. At corners or crossings, add a few taller lights to prevent dark stretches that may feel unsafe.

Urban Commercial Zones: High-Density Lighting

Commercial lighting poles in busy business areas with heavy vehicle and pedestrian traffic typically range from 4.27 -6.1 m (14 -20 ft). In districts with tall buildings, commercial light poles may be 6 -12 m to project light over obstructions. This height strategy delivers wide-area coverage, reduces shadows cast by buildings, and supports 24/7 lighting needs in commercial zones.

Highways and Arterial Roads: Long-Range Visibility

Highway light pole on highways or city street light pole on main roads are often about 7 -12 m (25 -40 ft), and in some cases extend to 12 -15 m to provide long-distance coverage. Some design guides suggest 30 -50 m spacing per pole. These ranges appear in many manufacturer catalogs and project case studies. However, major international light pole standards(e.g., EN 13201, CIE guidance) do not fix pole heights; final highway lamp post should be selected based on performance needs such as illuminance, uniformity, and glare control.

For tunnel lighting, IEC 60598-2-3 requires a minimum pole or fixture height of 2.5 m, to make sure low structures do not block the light. Beyond this, in custom projects (like large event venues or smart city sites),street light with pole heights may be designed at 10 m, 15 m, or even 20 m, to support communication, decoration, or other functions.

Design Rationale: Optimizing Light and Energy

The light pole length has a big effect on light spread and energy use. For example, residential street light pole(3 -3.66 m) use smaller LEDs (20 -50W) to give 15 -30 lux of soft light.freeway light pole (7.62 m or more) use bigger lights (100 -200W) to give 50 -100 lux over long distances. This step-by-step setup avoids too much light in quiet areas and gives safe visibility in high-speed zones. It also follows global energy-saving ideas, like the pilot project in Neath Port Talbot, Wales, where lights were set by real usage.In short, choosing the right height lamp post means balancing technical rules (IEC, ASTM), scene needs, and the environment. As cities grow, using flexible pole heights and adding extra functions (like 5G or solar) will be key for efficient, future-ready lighting.

Technical Parameters and Materials

The strength and life of standard-height streetlight poles mainly depend on their materials and technical specs. These decide the safety of the structure, the cost of upkeep, and how well the pole fits different environments. This part will show the key materials, main specs, and the international rules used in making them.

Material Selection and Durability

How long a led street light pole lasts depends first on the material. galvanized steel light pole is most common for city and road projects, as it is strong and low-cost. For places with strong winds or long arms, stronger steel is needed. In coastal or salty areas, weathering steel or aluminum poles work better because they fight rust and lower upkeep costs.

To make street lighting poles last longer, surface protection is important. Hot-dip galvanizing (HDG) adds a zinc layer of 80 C100 m or more, giving strong rust protection. Powder coating can be added for better looks and extra defense. The final protection should match the environment and how long the led light on pole is meant to last.

Core Technical Parameters

Structural Specifications

The pole thickness of a street light pole depends on its height, configuration (e.g., a single arm light or a double arm solar street light pole), and the wind load. In general, poles 2 -4 m high use about 2.5 mm pole thickness; poles 4 -9 m high use 3 -3.5 mm; and poles 8 -15 m high need 4 -6 mm. For higher-wind sites or larger arms/solar assemblies, increase the pole thickness to keep the pole safe and stable over the long term.

Welding: The pole uses automatic submerged-arc welding with ultrasonic testing, meeting (AWS D1.1 / BS EN 1011 standards). This is used for 8 -20 m high poles to keep welds strong and safe under heavy wind. For tall light pole joints, pin and set-screw fixing is used to stop loosening over long use.

Arm configuration: street light arm configuration and lighting power are closely tied to pole height. Low poles (3 -6 m) usually use a single arm with 20 -50 W LEDs, giving 15 -30 lux for walkways without glare. Medium poles (8 -12 m) often adopt double or triple arms with 70 -150 W LEDs, covering 20 -50 m for city streets. High poles (12 -20 m) may require triple or quadruple arms with 150 -200 W LEDs or even HID lamps, providing wide, uniform light for highways and plazas.

Installation: For outdoor light post installation, the pole is fixed with anchor plates and bolts (ASTM A153 galvanized; yield strength 50,000 psi). It is set in concrete to withstand winds up to 300 km/h and seismic loads up to intensity 8.

Optical and Electrical Performance

LED technology dominates modern led lighting due to its?energy efficiency?(100 lm/W) and long lifespan (50,000 hours), reducing led bulb power consumption by 50-60% compared to traditional sodium-vapor lamps. But the setup must match the pole height:

Low poles (3-6 m, homes/paths): Often use 20-50 W LEDs, color 3000 -4000 K. This gives soft light with low glare. A 120 beam keeps light even in small areas, good for walkers.

Medium poles (8 -12 m, city roads): Use 45 -90 W LEDs, color 4000 K (neutral white). Lights turn on at 35 lux and off at 18 lux by photocells. The 120 beam gives even light on streets, meeting IEC 60598-2-3.

High poles (12 -20 m, plazas/highways): Need 150 -200 W LEDs or more, to cover wide areas and fast traffic. These lights focus on safety with IP65 (dust/water proof) and IK08 (impact safe), so they work well in bad weather and at tall heights.

International Standards and Compliance

Adherence to global standards is paramount for cross-market acceptance:

Galvanization: ASTM A123 / EN ISO 1461 specifies zinc coating thickness and adhesion, preventing premature corrosion in high-humidity or coastal areas.

Structural Safety: IEC 60598-2-3 governs outdoor luminaires, mandating electrical insulation, short-circuit protection, and thermal management (operating temperatures from -30 -to 50 C).

Material Testing: Tensile strength (360 -630 MPa), yield strength (235 -355 MPa), and elongation (20-24%) are verified via mechanical tests, ensuring poles meet wind load and deflection limits (0.5 -1.0 degrees under operational speeds).

Using high-grade galvanized steel, precise manufacturing (like submerged-arc welding), and meeting ASTM/EN rules makes street light poles last over 20 years with very little upkeep. Adding LED lights also improves energy savings and light quality.

International Certifications and Compliance

In the world market, certifications are the key for street light poles to join city and public projects. They decide if a product is legal, can be bought, and if people trust the brand.

CE Certification (Europe)

Required by law, based on EN 60598-2-3 (electrical safety, strength, protection).

Steps: tests by third party, technical files, Declaration of Conformity, and CE mark.

Since 2023, also needs eco-design and energy rules, asking for modular, green, and efficient design.

ENERGY STAR (North America)

Run by EPA/DOE, asks for 2300 lm light, 50 lm/W efficiency, and life 15,000 hours (California Title 24 also needs CRI >90).

Helps get energy rebates and gives priority in government buying. It is now a common rule for city and business lighting.

Other Standards

ASTM A123 / EN ISO 1461: hot-dip galvanizing for rust protection.

IEC 60598-1/2-3: electrical and structural safety for lighting.

RoHS / REACH / WEEE: rules for green design and recycling.

? Advantage: Certified poles can enter target markets, improve bid success, and meet global needs for safety, energy saving, and sustainability.

FAQs

1. What is the most common height for street light poles?

Most city roads use poles between 8 C12 meters, while residential areas often use 3 C6 meters, and highways use 12 C15 meters.

2. How do I know which pole material to choose?

For standard city roads, galvanized steel is most common. In coastal or high-salt areas, weathering steel or aluminum poles are better for corrosion resistance.

3. Are street light poles required to meet international standards?

Yes. Poles and luminaires must follow rules like EN 60598-2-3, EN 13201, and ANSI C136, and often need certifications like CE or UL for market entry.

4. How long can a street light pole last?

With hot-dip galvanizing and proper surface treatment, poles can last 20 years or more with minimal maintenance.

5. What lighting power matches different pole heights?

3 -6 m poles: 20-50 W LED, soft light for walkways

8-12 m poles: 45 -90 W LED, neutral white for city roads

12-20 m poles: 150 -200 W LED or more, wide coverage for highways and plazas

If you send us your road drawings, we can design a full lighting layout for you.