When street lights turn purple, it is not just a strange color change. It is a sign of a reliability problem. For cities and utilities,purple streetlights quickly cause public complaints, social media posts, and urgent repair work. For EPC contractors and procurement teams, the problem raises hard questions. Was the product specification unclear? Did a batch in the supply chain fail? Can the warranty work without clear traceability?

This guide explains, in very simple terms, what do the purple street lights mean in LED physics, why the problem often appears in groups, and how to respond with a clear, repeatable process. The focus is practical and B2B: find the real cause, fix it correctly, and stop it from happening again by using procurement rules that require proof, responsibility, and enough thermal margin—without adding unnecessary specifications.

Figure01

Key Takeaways

Most cases of LED street lights turning purple are caused by failure inside the LED package, usually the phosphor or protective coating. It is not caused by a simple driver setting. The purple color often appears in groups, which means it is linked to material batches or production changes. Until proven otherwise, this should be treated as a system-wide problem.

The correct response is clear and practical: first define the affected area, then collect serial numbers, request technical documents and traceability, and finally carry out a warranty replacement plan. IP ratings help protect against water and dust, but IP alone cannot stop purple color shift. Heat, electrical stress, and the strength of the LED package matter much more.

To prevent this issue, projects need proper thermal testing, a stable drive design, full traceability, and clear warranty terms that define serious color change as a failure. A low-cost street light may look cheap at purchase, but once you add site visits, traffic control, labor, and damage to reputation, it can become the most expensive option.

What “Street lights purple” Usually Means in LED Physics

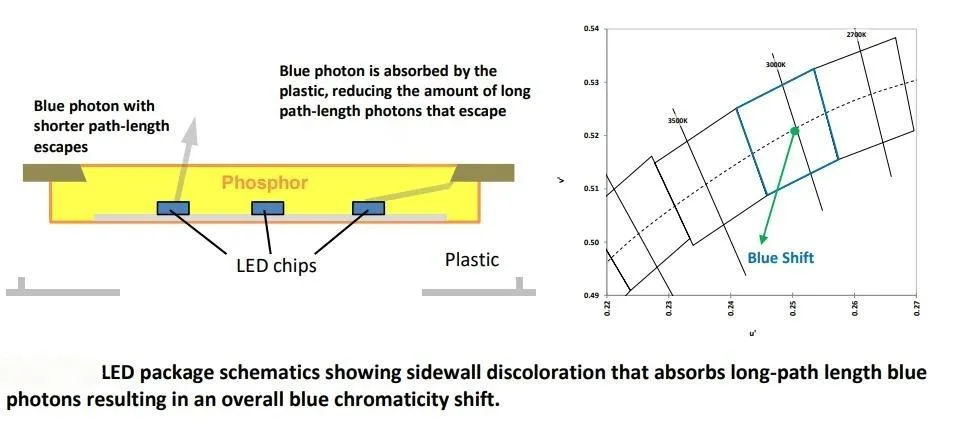

Most road lights use phosphor-converted white LEDs. A blue LED chip makes narrow blue street light. A phosphor layer changes part of that energy into wider yellow and red light. When these mix, the light looks white.

If this conversion system becomes weaker or its structure changes, less blue light is converted. More blue purple light escapes. The spectrum becomes blue-heavy, and the light can look blue-purple, violet, or pink-purple. The exact color depends on how much conversion is left and how the optics mix the light.

Figure02

Why it looks purple (not just “cooler white”)

Purple lamp light usually comes from two things happening together:

A stronger blue peak that leaks through

Much less yellow and red light from the phosphor

At night, human eyes make this color change look even stronger. That is why complaints appear quickly, even though the light still turns on.

From an asset management point of view, visible purple light is rarely harmless. It is often a sign of a failure that can affect many lights from the same batch or installation period.

The Most Common Root Cause: Package and Phosphor System Failure

For B2B troubleshooting, it’s helpful to separate “electrical control issues” from “LED package conversion issues.” Most purple events fall in the second category.

Phosphor conversion degradation

Phosphor materials are designed to last, but they can weaken over time. Long exposure to high heat, very strong light, chemical contact with packaging materials, or dirt and defects from manufacturing can cause stress. When the phosphor becomes weaker, it converts less blue light. As a result, the light appears cooler. If the damage is severe or the structure changes, the color may shift to purple or violet.

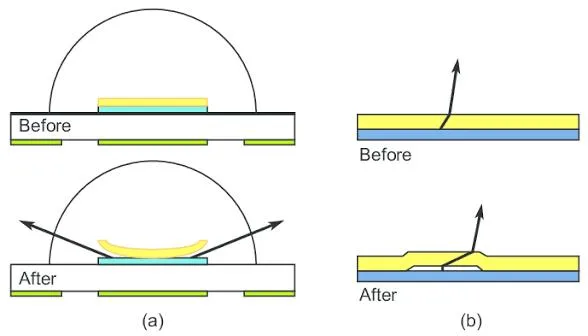

Encapsulant cracking, yellowing, and delamination

The encapsulant is often made of silicone and protects the LED die and the phosphor system while helping guide the light correctly. Over time, the encapsulant can fail. Heat cycling can cause cracks, and the material can turn yellow depending on its formula and use conditions. The layers can also separate, which is called delamination. Delamination is a common cause of “blue street lights” because it changes the light paths inside the package. When this happens, some phosphor is no longer in the correct position over the blue chip, more blue light leaks out, and color conversion becomes uneven.

Field clue: if the purple color looks uneven or patchy, the problem is often inside some LED packages, not a setting or control issue affecting the whole light.

Figure03

Why it happens in batches

Batch problems often have the same cause. Small changes in material lots, such as phosphor, silicone, package parts, or bonding, can trigger failure. Process changes, like curing, coating thickness, or cleanliness, can also cause issues. Supplier changes matter too. In some cases, the light design runs close to its heat limit, so even small differences can push it over. If many fixtures turn purple around the same time, assume a system problem and take action.

Contributing Factors That Accelerate Purple Shift in the Field

Even if the root cause is at the LED package level, luminaire design and operating conditions determine how quickly the symptom becomes visible.

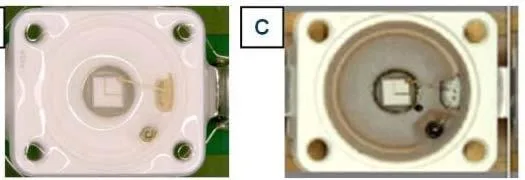

Thermal stress and insufficient margin

Thermal margin is a hidden cause of many reliability problems. It is reduced by small heat sinks, poor airflow, or weak thermal interface materials. High outdoor heat, heat-island areas, enclosed pole-top designs, dirt buildup, and high power in small housings all raise temperature. A light can pass early tests and still fail early if it runs close to the LED limits. For buyers, “works in the lab” does not mean it is safe in real use.

Figure04 shows LED housing damage caused by long-term high temperature. The heat source may differ, but the result is the same. When thermal margin is gone, materials age faster and reliability drops.

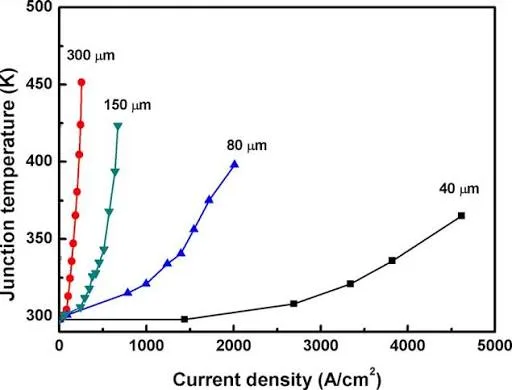

Drive current, ripple, and electrical stress

Drivers are not always the main cause of purple color shift, but they can speed up package degradation. High current density raises junction temperature and adds stress to the LED. High ripple current creates extra heating and fatigue over time. Gaps in surge protection can cause partial damage that slowly worsens. This is why lights with the same wattage do not always have the same reliability. The drive strategy and the real operating conditions of the LED matter.

Figure05 illustrates how different drive strategies affect LED operating stress. Higher current density, ripple, and surge exposure raise junction temperature and accelerate package aging, even when the rated wattage is the same.

Optics, sealing, and environment

Optical parts and sealing can add extra stress to a light. Dirt and pollution block light and raise internal temperature. Weak seals let moisture and contaminants enter over time. Salt fog near the coast and industrial chemicals speed up aging. An IP rating alone does not ensure long-term stability. Real protection depends on design details, build quality, and repeated pressure and humidity changes, not just the IP number.

How to Diagnose Purple Street Lights Correctly

Many teams waste time assuming the driver or control system is responsible because “color change” sounds like a setting. A better diagnostic approach uses probability plus evidence.

Step-by-step field checklist

Confirm pattern and scope

Start by counting how many fixtures are affected and mark their locations on a map. Compare installation dates and delivery batches to see if the failures line up in time. When purple bulb lights appear in clear batches or clusters, it usually points to a systemic issue related to materials, manufacturing, or the supply chain, rather than random field damage.

Check stability

Observe whether the light output is stable or unstable. Look for flicker, cycling, or intermittent behavior. If the output is unstable, driver or power quality problems may be involved. If the purple color is stable and steady, package-level color conversion failure becomes the more likely cause.

Assess uniformity of purple across the luminaire

Check whether the purple color is uniform across the entire LED array. A uniform purple appearance usually indicates that many LED packages or modules have experienced similar conversion failure. Patchy or uneven purple output suggests partial failures, localized overheating, or mixed material lots within the same luminaire.

Inspect external condition

Inspect the external condition of the fixture carefully. Check the lens cover for dirt buildup, sealing issues, impact damage, or visible signs of moisture. External contamination or sealing failure can increase internal stress and accelerate aging.

Capture identification data (non-negotiable)

Always record key identification data, including serial number or QR code, model, wattage, installation date, and pole ID or GPS location. This information is essential for warranty claims and batch-level root cause analysis. If your organization manages large outdoor assets such as networks across multiple areas, use a standard incident capture form so every maintenance team collects the same data in a consistent way.

What to request from the supplier

A reliable B2B supplier should give clear documents. These include an LM-79 report for light performance and color, LM-80 data with a TM-21 lifetime method, and LED package datasheets with safe operating limits. The driver datasheet should explain quality and reliability. The supplier should also show surge protection and grounding methods. They must link serial numbers to LED and driver batches and explain the warranty plan, including lead time, spare parts, and fixes.

When to pull samples for lab analysis

Lab analysis is useful in some cases. It helps when suppliers dispute responsibility or when failures happen at a large scale, such as across a city or multiple project phases. It is also important when you need strong evidence to update specifications. Testing a small number of fixtures with spectral checks and physical inspection can help avoid repeated site visits later.

Solutions That Actually Work: Immediate Actions and Long-Term Prevention

A reliable response plan handles two timelines: immediate service continuity and long-term prevention.

Immediate actions (operational)

Start with high-risk areas such as fast roads, intersections, crossings, and security routes. Explain clearly that the issue is not planned and share the fix plan and timeline. Use temporary actions if needed, such as moving lights from low-priority areas or adding short-term lighting. If your system also includes work, plan lane closures and permits together to avoid repeat disruption.

Warranty and replacement strategy (how to win without drama)

Purple shift should be treated as functional failure when it materially changes roadway appearance and visual performance. Successful warranty enforcement depends on evidence, not volume.

Document:

Affected count and failure rate vs install date

Serial numbers and location mapping

Photos of purple output

Environmental notes (coastal/industrial/high-heat zones)

Maintenance logs and relevant event history (storms/surges where available)

Request:

Written acknowledgement + replacement timeline

Batch-based replacement plan (not only the visibly purple units if systemic risk is evident)

Confirmation of corrective actions in production (materials/process/package changes)

Engineering prevention: what actually reduces purple risk

Thermal margin: verify LED temperatures under worst-case ambient and mounting conditions.

Drive strategy: avoid aggressive overdrive; use stable current, low ripple; confirm surge resilience.

LED package selection: proven long-term stability with transparent reliability data.

Process control + traceability: ensure lot-level mapping and consistent materials.

If you also deploy {{highbay led light}} indoors, note that indoor products often face less thermal cycling and environmental stress. Don’t assume indoor reliability experience transfers directly to roadway conditions.

Practical Troubleshooting Table: Symptoms → Causes → Checks → Fix

| Symptom | Likely cause | What to check | Practical fix |

| Uniform purple across many fixtures in same install window | LED package conversion failure (phosphor/encapsulant/delamination) | Batch pattern, serial/lot traceability, spectral shift evidence | Warranty batch replacement + corrective action confirmation |

| Patchy purple, hotspots, mixed colors | Partial module failures, localized overheating, mixed lots | Module layout, thermal interface consistency, moisture signs | Replace modules/fixtures; review assembly + thermal margin |

| Flicker/cycling plus color oddities | Driver instability / wiring / power quality | Driver output, wiring integrity, surge damage evidence | Repair/replace driver; verify surge + grounding |

| Purple after severe weather | Surge or ingress accelerates damage | SPD approach, seal integrity, condensation/corrosion | Replace affected; improve surge/ingress strategy |

| Gradual “too cool” then purple | Progressive conversion decline under stress | Timeline vs ambient/temp zones, operating hours | Replace; tighten thermal + drive spec |

Procurement Spec Template to Prevent Purple Failures

This is written to reduce purple-risk while keeping bids competitive.

Must-have vs Nice-to-have

| Category | Must-have | Nice-to-have |

| Documentation | LM-79; LM-80 + TM-21 method disclosure | Third-party audits, extended field data |

| Traceability | Serial/QR + mapping to LED/driver lot + production date | Digital asset integration, QR to maintenance history |

| Thermal verification | Evidence of acceptable LED temperature under worst-case ambient | CFD reports, extended high-ambient testing |

| Electrical robustness | Surge approach + driver stability disclosures | Remote monitoring diagnostics |

| Warranty | Color shift defined as failure + SLA for replacement + batch handling plan | On-site swap support, extended warranty |

| Quality control | Process control summary + incoming inspection approach | Full supplier quality manual access |

Copy-ready spec checklist

Provide LM-79 luminaire test report including chromaticity data.

Provide LED package LM-80 data and TM-21 projection approach used for lifetime claims.

Define severe chromaticity shift (e.g., “purple street lights”) as a failure condition requiring corrective action under warranty.

Provide thermal verification evidence demonstrating acceptable LED operating temperature at specified ambient conditions and mounting scenarios.

Require traceability: fixture serial/QR linked to LED lot, driver lot, and production date.

Require written warranty response SLA and batch failure remediation process.

Require supplier corrective action summary when abnormal failure rates occur.

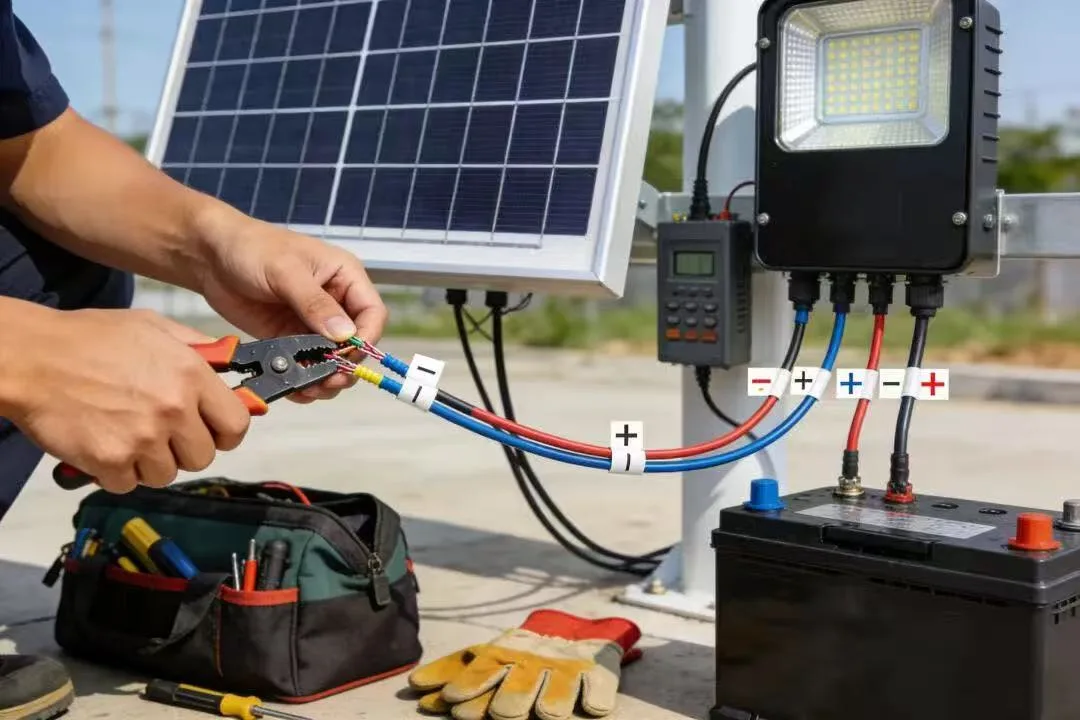

If you procure {{solar led street light}} systems, use the same traceability discipline while adding controller and battery traceability requirements and environmental suitability proof.

Cost, Risk, and ROI: Why the Cheapest Fixture Can Be the Most Expensive

Purple-light incidents create hidden lifecycle costs: labor, lift equipment, traffic control, logistics, administrative time, and reputational damage.

| Scenario | Direct costs | Indirect costs | Typical outcome |

| Normal operation | Routine maintenance | Low complaint load | Predictable lifecycle cost |

| Purple batch event | Truck rolls, labor, replacements, inventory | Public complaints, safety perception, political attention | Cost spike + repeated disruption if not batch-managed |

A slightly higher unit price can be cheaper overall if it buys thermal margin, traceability, and enforceable warranty response.

If your city has high-visibility zones with decorative assets like {{led garden light}} or public plazas, public reaction to color inconsistency can be faster and louder—another reason to treat color stability as part of functional performance.

Conclusion

Street lights turning purple are typically the visible outcome of LED package conversion system failure, often amplified by thermal and electrical stress and revealed through batch patterns. The winning response is disciplined: map failures, capture serials, request documentation and traceability, execute a batch-aware replacement plan, and lock prevention into future procurement language.

If you want fewer surprises, don’t chase only headline lumens and IP ratings. Demand evidence (LM-79/LM-80/TM-21 concepts), thermal verification, traceability, and warranty SLAs. That combination reduces the probability of purple events and makes recovery faster when they occur.

For broader outdoor portfolios—parking canopies, transit hubs, or service areas—apply the same discipline to {{led canopy light}} categories so reliability expectations stay consistent across projects.

FAQ

Why are street lights turning purple?

Most cases involve LED package conversion failure. White LEDs depend on a blue source plus a phosphor conversion layer. When conversion weakens or delaminates, more blue leaks through and the apparent color shifts toward purple/violet.

Are purple street lights dangerous?

Not inherently electrically dangerous, but they can be operationally problematic: altered visual perception, public concern, and potential indication of a broader batch reliability issue requiring prioritized remediation.

Is the driver causing LED street lights turning purple?

Drivers can contribute via instability or stress, but stable purple output across many fixtures in one install window most often points to package conversion issues rather than a simple driver setting.

Why does it happen in batches?

Batch patterns often trace back to material lots, process changes, or supplier substitutions in LED packaging, sometimes amplified by limited thermal margin in the luminaire design.

Can you fix purple street lights without replacing the fixture?

Usually no. Because the issue is inside the LED package structure, external adjustment rarely restores normal color. Replacement (fixture or modules) is the practical remedy.

How should municipalities handle warranty replacement?

Collect serials, map locations, quantify failure rate by install date, and define severe color shift as failure. Request a written replacement plan, lead time, and confirmation of corrective actions to prevent recurrence.

What specs reduce the risk of street lights turning purple again?

Require LM-79, LM-80 and TM-21 method disclosure, thermal verification under worst-case ambient, strong traceability (LED and driver lots), and warranty SLA language that treats severe color shift as a functional failure.

Does a higher IP rating prevent purple street lights?

Higher IP can reduce ingress risk but does not guarantee against purple shift. Prevention depends more on thermal margin, stable electrical design, robust LED packaging, and quality control with traceability.