Introduction

When it comes to outdoor gas station operations, lighting is far more than just a way to illuminate the area after dark. It’s a critical factor that impacts safety, customer experience, brand reputation, and long-term operational costs. In recent years, led canopy lights have emerged as the gold standard for gas station lighting, replacing traditional HID (high-intensity discharge) lamps and fluorescent led light bulbs. But with so many options on the market, how do you select the right led canopy lights for your classic gas stations?

This comprehensive guide will walk you through everything you need to know—from understanding your lighting needs and complying with industry standards to adapting to harsh weather conditions and calculating return on investment (ROI). Whether you’re building a new gas station, renovating an existing one, or upgrading outdated lighting, this article will help you make informed decisions that align with your business goals.

Understanding Canopy led lights: What They Are and Why They Matter for Gas Stations

Before diving into (selection), it’s essential to clarify what canopy lights led are and why they’re the ideal choice for gas stations. Unlike traditional lighting solutions, led lights canopy are specifically designed to be installed under overhead canopies—common in gas stations, parking garages, and covered walkways. They’re available in two primary installation styles: surface-mounted (attached directly to the canopy ceiling) and recessed (installed into the ceiling for a sleek, low-profile look).

Key Benefits of led canopy lights for gas station

Energy Efficiency: Canopy lights for gas station consume 50-70% less energy than metal halide light fixture and led light bulbs for fluorescent fixtures. For a gas station with 10 canopy lights running 12 hours a day, this could translate to annual electricity savings of over 6,000 (based on 0.15/kWh).

Long Lifespan: Most canopy lights for gas station offer a lifespan of 50,000+ hours—three to five times longer than HID lamps. This reduces the frequency of replacements, cutting down on maintenance costs and labor.

Superior Lighting Quality: LED technology provides consistent, uniform illumination with high color rendering index (CRI) values (typically ≥80). This ensures that fuel pump labels, price signs, and vehicle details are clearly visible, enhancing safety and customer trust.

Durability: Led canopy light for gas station are built to withstand the unique challenges of gas station environments, including exposure to fuel vapors, dust, and extreme weather.

Why Traditional Lighting Falls Short

Traditional metal halide light bulbs and fluorescent fixtures have significant drawbacks for gas stations:

High Energy Consumption: 250w metal halide light use far more electricity than equivalent LED models (e.g., 100W LED).

Short Lifespan: HID lamps typically last 10,000-15,000 hours, meaning they need to be replaced every 1-2 years.

Poor Temperature Performance: Led fluorescent light fixtures struggle in cold weather, often failing to start or producing dim light in temperatures below 40°F (4°C).

Glare Issues: High pressure sodium light fixture often produce harsh glare, which can distract drivers and increase the risk of accidents—especially critical in gas stations where vehicles are constantly moving.

Step 1: Assess Your Gas Station’s Lighting Needs (Before You Buy)

The first and most critical step in selecting gas station canopy led lights is to assess your specific needs. Every gas station is unique, and factors like size, layout, and location will influence the type of lighting you require. Skipping this step can lead to overspending, poor illumination, or non-compliance with regulations.

Evaluate Canopy Size and Layout

Canopy Height: The height of your canopy determines the wattage and beam angle of the LED lights you need. For example:

6-meter (20-foot) canopies: 100w led canopy lights with a 60-90° beam angle are typically sufficient.

9-meter (30-foot) canopies: 150-200w led canopy light with a 90-120° beam angle are recommended to ensure uniform coverage.

Number of Fuel Pumps: More pumps mean more coverage area. For a gas station with 4-6 pumps, you’ll likely need 8-12 gas station canopy lights. For larger stations with 8+ pumps, 12-16 lights may be necessary.

Layout Type: Single-row pump layouts require symmetric beam angles, while double-row or multi-row layouts may need a mix of symmetric and asymmetric beam angles to avoid shadows between pumps.

Define Illumination Goals

Average Illuminance: Gas stations require specific levels of brightness to ensure safety. According to China’s GB 50034 Standard, the average illuminance (E??) for gas station ground areas should be ≥100 lux, and ≥50 lux for fuel pump surfaces. For Sinopec (China Petroleum & Chemical Corporation) stations, the

standard is even higher: 150-200 lux for work areas and ≥75 lux for pump surfaces.

Uniformity: Illuminance uniformity (the ratio of minimum to average illuminance) is equally important. Most standards require a uniformity ratio of ≥0.4 (e.g., Sinopec specifies 0.4-0.7) to avoid dark spots or overly bright areas.

Color Temperature (CCT): The ideal led lamp color temperature for gas stations is 4000K-5000K. This “cool white” light balances visibility with comfort—warm white (3000K) can make the area feel dim, while cool white (6000K+) may cause glare.

Consider Regulatory Requirements

Compliance with local and industry standards is non-negotiable. Here are the most common regulations to keep in mind:

GB 50034 (China): Covers illuminance, CRI (≥60), color temperature (4000K/5000K), and lighting power density (LPD ≤6W/m2).

Sinopec Standards: More stringent than GB 50034, requiring CRI ≥80, LPD 8-10W/m2, and higher illuminance for work areas.

ATEX/IECEx Certification: For gas stations (classified as hazardous areas due to fuel vapors), gas station led canopy lights must have ATEX or IECEx 防爆 (explosion-proof) certification to prevent sparks from igniting flammable gases.

DLC Certification (North America): The Design Lights Consortium (DLC) certifies energy-efficient lighting products. DLC Premium certification ensures that LED canopy lights meet strict efficiency and performance standards, and may qualify you for utility rebates.

Key Technical Specifications to Look for in LED Canopy Lights

Once you’ve defined your needs, the next step is to evaluate the technical specifications of gas canopy led lights. These specs directly impact performance, durability, and cost-effectiveness. Here’s what to prioritize:

Energy Efficiency (lm/W)

The most important metric for energy efficiency is lumens per watt led (lm/W)—the amount of light produced per unit of electricity consumed. Look for gas canopy lights with a lm/W rating of ≥130.

For example:

A 100w led canopy light with 16,500 lumens has a lm/W rating of 165—far more efficient than a 250w metal halide bulb with 20,000 lumens (80 lm/W).

Higher lm/W ratings mean lower electricity bills. A gas station using 10 x 100w led canopy light(165 lm/W) will use 1,200 kWh per year, compared to 10 x 250w metal halide bulb (3,000 kWh per year)—a savings of 1,800 kWh annually.

Ingress protection ratings (IP and IK)

Gas stations expose lighting to dust, rain, snow, and potential impacts. Two ratings measure a light’s ability to withstand these conditions:

IP (ingress protection scale) Rating: Measures(dust) and(water) resistance. For gas stations, IP65 or IP66 is required:

IP65: Fully dust-tight and protected against low-pressure water jets (e.g., heavy rain).

IP66: Fully dust-tight and protected against high-pressure water jets (e.g., storms or pressure washing).

IK (Impact Resistance) Rating: Measures resistance to mechanical impacts. Look for IK10—the highest rating, meaning the light can withstand a 10J impact (e.g., a falling tool or debris).

Durability and Materials

The materials used in led lights gas stations determine their lifespan and resistance to corrosion:

Housing: Die-cast aluminum is the best choice. It’s lightweight, heat-resistant, and corrosion-proof—critical for gas stations near the coast (where saltwater can corrode metal) or in industrial areas (where chemicals may be present).

Lens: Polycarbonate (PC) lenses are preferred over glass. They’re shatterproof, UV-resistant (to prevent yellowing), and can withstand extreme temperatures (-40°F to 140°F / -40°C to 60°C).

Seals: Look for lights with silicone gaskets instead of rubber. Silicone is more durable and resistant to aging, ensuring long-term waterproofing.

Thermal Management

LEDs generate heat, and poor heat management can reduce lifespan and performance. High-quality gas station light fixtures include:

Integrated Heat Sinks: Die-cast aluminum housings often double as heat sinks, dissipating heat efficiently.

Thermal Paste: A layer of thermal paste between the LED chip and heat sink improves heat transfer.

Overheat Protection: Some models include a built-in sensor that reduces power if the light overheats, preventing damage.

Warranty and Lifespan

A strong warranty is a sign of quality. Look for LED canopy lights with:

Lifespan: ≥50,000 hours (equivalent to 17 years if used 8 hours per day).

Warranty: 5-10 years of coverage for the entire light (not just the LED chips). Avoid lights with only 1-2 year warranties—they may use low-quality components.

Adapting to Harsh Weather: How to Choose LED Canopy Lights for Extreme Conditions

Gas stations operate in every climate—from the freezing winters of northern China to the humid summers of the south, and the storm-prone coasts of Southeast Asia. Choosing gas station led lights that can withstand these conditions is critical to avoiding downtime and costly repairs.

Extreme Temperatures

Cold Weather (-40°F to 32°F / -40°C to 0°C):

Look for lights with a wide operating temperature range (-40°C to 60°C).

LED lights with low-temperature startup capability (no preheating required) are essential—traditional HID lamps often take minutes to reach full brightness in cold weather.Avoid lights with plastic components that may become brittle in the cold; die-cast aluminum housings are more durable.

Hot Weather (95°F to 140°F / 35°C to 60°C):

Prioritize lights with efficient heat sinks to prevent overheating.

Choose models with a high maximum operating temperature (≥60°C).

Avoid lights with enclosed designs—ventilated housings help dissipate heat.

Rain, Snow, and Humidity

Heavy Rain or Storms: IP66-rated lights are ideal, as they can withstand high-pressure water jets. Ensure the light’s electrical connections are sealed with waterproof wire nuts or connectors.

Snow: Look for lights with a smooth, sloped top to prevent snow buildup (which can block light and add weight to the canopy). Some models also include a heating element to melt snow, though this increases energy consumption.

High Humidity: Corrosion is a risk in humid environments. Choose lights with anti-corrosion coatings (e.g., powder coating) and stainless steel hardware (to prevent rust).

Coastal and Salty Environments

Saltwater spray is highly corrosive. For gas stations near the coast:

Choose lights with marine-grade aluminum housings (treated to resist salt corrosion).

Look for stainless steel screws and brackets instead of galvanized steel.

Regularly clean the lights with fresh water to remove salt buildup—this can extend lifespan by 2-3 years.

Dust and Sandstorms

In arid or desert regions, dust and sand can clog vents and damage components:

IP65 or IP66-rated lights are dust-tight, preventing particles from entering the housing.

Avoid lights with external fans (which can suck in dust). Instead, choose passive cooling systems (e.g., heat sinks).

Schedule quarterly inspections to clean the lens and vents—dust buildup can reduce light output by 20-30%.

Calculating ROI: How LED Canopy Lights Save Money Over Time

While gas station led light fixtures have a higher upfront cost than traditional lighting, their long-term savings make them a smart investment. Here’s how to calculate the ROI for your gas station:

Upfront Costs

The cost of gas station canopy led varies based on wattage, brand, and features:

led canopy light 100w: 60-100 (ATEX-certified models may cost 120-180).

led canopy light 150w: 80-140 (ATEX-certified models: 150-220).

For a gas station with 10 lights, upfront costs could range from 600-2,200, depending on certification and features. Traditional HID lights may cost 300-800 upfront, but the long-term savings of LED far outweigh the difference.

Energy Savings

To calculate annual energy savings:

Determine the wattage of your current lights (e.g., 250W HID).

Calculate the annual energy use of current lights: (Wattage ÷ 1000) × Hours per day × Days per year.

Example: 250W HID × 12 hours/day × 365 days = 109.5 kWh per light per year.

Calculate the annual energy use of LED lights (e.g., 100W LED):100W LED × 12 hours/day × 365 days = 43.8 kWh per light per year.

Calculate savings per light: 109.5 kWh – 43.8 kWh = 65.7 kWh per year.

Multiply by the number of lights and electricity cost (e.g., $0.15/kWh):

10 lights × 65.7 kWh × 0.15/kWh = 98.55 annual savings.

For 10 lights, this translates to nearly 100 in annual energy savings. Over 5 years, that’s 492.75—more than covering the upfront cost of the LED lights.

Maintenance Savings

Traditional HID lights need to be replaced every 1-2 years, while LED lights last 5-10 years. Maintenance costs include:

Replacement Bulbs: HID bulbs cost 20-50 each. For 10 lights replaced annually, that’s 200-500 per year. LED lights require no bulb replacements for 5+ years.

Labor Costs: Hiring an electrician to replace bulbs costs 50-100 per hour. For 10 lights, this could be 100-200 per year for HID, compared to $0 for LED (for 5+ years).

Over 5 years, maintenance savings for 10 lights could be 1,500-3,500—far exceeding the upfront cost of LED lights.

Total ROI

Combining energy and maintenance savings, the total ROI for LED canopy lights is typically 1-3 years. For example:

Upfront cost: $1,500 (10 ATEX-certified LED lights).

Annual savings: 98.55 (energy) + 300 (maintenance) = $398.55.

ROI: 1,500 ÷ 398.55 ≈ 3.76 years.

For gas stations with higher electricity costs or more lights, ROI can be as short as 1 year.

Installation and Maintenance Tips for Long-Term Performance

Even the best LED canopy lights will underperform if installed or maintained poorly. Follow these tips to ensure optimal performance:

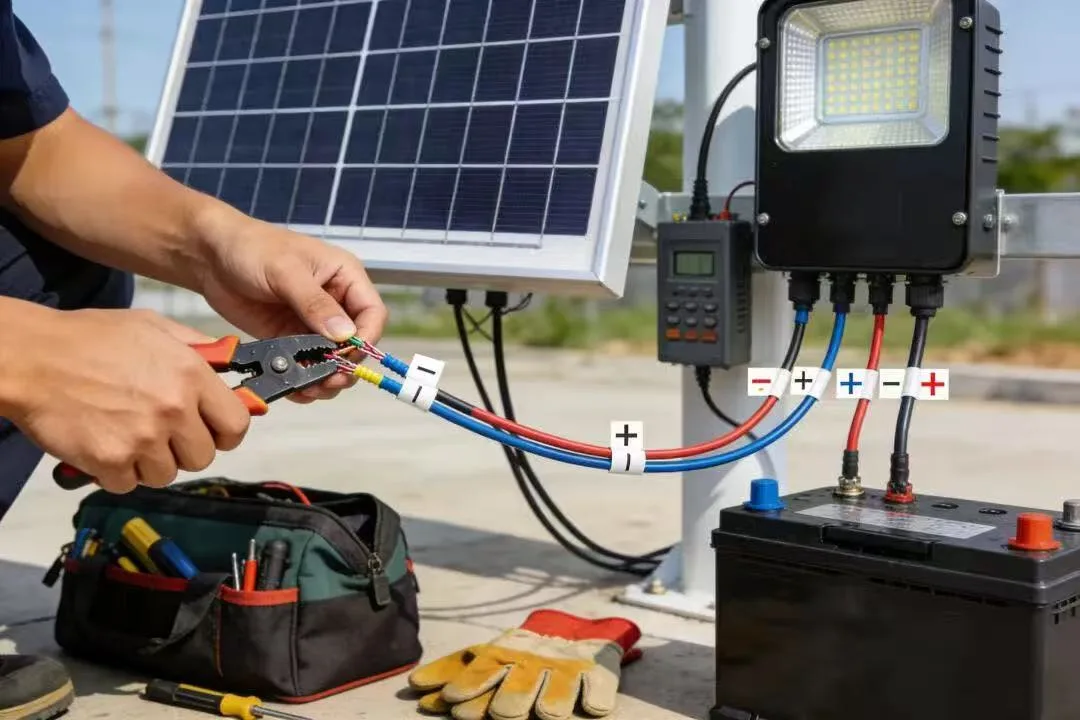

Installation Best Practices

Hire a Licensed Electrician: Gas stations are hazardous areas, so installation must be done by a professional with experience in (explosion-proof) lighting.

Follow Manufacturer Guidelines: Ensure the light is installed at the recommended height and spacing. For example, 100W LED lights should be spaced 4-6 meters apart for uniform coverage.

Secure Mounting: Use heavy-duty brackets and expansion bolts to secure

FAQ

Q1: Are LED canopy lights suitable for long-term outdoor use?

Yes. High-quality LED canopy lights are designed with IP65 or IP66 protection ratings, making them waterproof, dustproof, and corrosion-resistant. They maintain stable performance in heavy rain, extreme heat, and cold weather conditions.

Q2: How much energy can I save compared to traditional HID lights?

LED canopy lights can reduce energy consumption by 50%–70%, depending on wattage and daily usage. For example, switching from 250W HID to 100W LED for 10 fixtures can save over 1,800 kWh annually, significantly lowering electricity bills.

Q3: Is installation complicated?

No. Most LED canopy lights support surface or recessed mounting and are designed for quick installation. However, for gas stations (especially in hazardous areas), it’s strongly recommended to hire a licensed electrician to ensure compliance with explosion-proof and safety standards.

Q4: Do I need ATEX/IECEx certified lights?

If your gas station is located in hazardous zones with fuel vapors, ATEX or IECEx certified explosion-proof lights are mandatory.

For standard outdoor use, high IP-rated lights (IP66) without explosion-proof certification are usually sufficient.

Q5: How long is the typical lifespan of LED canopy lights?

Premium LED canopy lights last over 50,000 hours, equivalent to 5–10 years of use without frequent maintenance—far exceeding HID or fluorescent lighting.

Ready to Upgrade? Maximize ROI with the Right LED Canopy Lights

When selecting canopy lighting, price should not be your only consideration. The right product can:

Cut electricity costs with high-efficiency LED technology

Reduce maintenance and replacement frequency

Enhance safety with reliable certifications and high protection ratings

Support green energy goals and regulatory compliance

Let our experts help you choose the right product.

We can recommend the ideal wattage, beam angle, and protection rating for your specific station layout and provide an ROI calculation report so you can see exactly how much you’ll save.

Contact us today to get your free customized lighting solution and quotation.