Introduction: The Hidden Economics of led street lighting

When a city lights up at night, few people notice this: outdoor led street lights use 30%–50% of the city’s yearly energy bill. In some places, public lighting led takes 60% of city power spending. It is a hidden cost.

As cities grow fast around the world, this “lights on means more use” problem is getting worse. By 2025, the global city led street lights roadway lighting market is expected to reach $20 billion—33% higher than in 2019.City managers often make a big mistake when making decisions: they only look at the purchase street lamp price. For example, commercial grade landscape lighting can cost 1.5 million per kilometer,which is five times more than on a normal road. This difference comes from more than 10 factors, such as project size, equipment choice, and maintenance system.

Even more important, traditional high pressure sodium lamps have “three highs”:High energy use: more than 50% higher than LED street lights.High maintenance cost: they need to be replaced 2–3 times each year.Short lifespan: only 15,000–20,000 hours.These hidden costs usually appear only after the project is in use.

Why Lifecycle Cost Matters More Than Upfront Savings

The “real price” of a street light is not the number on the purchase contract. Take LED street lights as an example. The upfront cost is 30%–50% higher than old fashioned led street light lamps. But LEDs last 50,000+ hours (about 3× sodium lamps), cut energy use by 60%+, and need almost no frequent part swaps. These gains can close the price gap in 3–5 years. Over the full life, the lifecycle cost is 40%+ lower than the old plan.

From a global view, this “lighting cost revolution” is urgent. The IEA reports the urban road-lighting market is growing 6.3% a year and will pass $20 billion in 2025. Better energy efficiency and net-zero goals make lifecycle cost (LCC) analysis the new standard. Whether it is 80 billion a year spent on road lighting in China, or $160 billion in global energy-saving potential, the message is clear: short-term, price-only choices make cities pay more for “cheap lights” in the long run.

Understanding led street light costs: Beyond the Initial Price Tag

Breaking Down Initial Costs by Light Type

When city departments or project owners buy streetlights led, the “first look price” often becomes the main focus. But the starting cost is very different for each types of led street light. light bulbs for street lights look more expensive because of the advanced technology inside. Traditional led lights for streets look cheaper, but they hide many extra costs later. solar led street lights cost more at first because they need batteries to store clean energy.

LED street lights often cost three to five times more than old lamps because they use high-tech parts. A Philips 15W unit is about €50. A Cree 25W smart model is about $180. A GE 70W high-power unit is about $220 .

A big share of the price sits in hidden parts. The driver (power supply) is about 15%–20% of the total. A Philips 75W driver alone is about $50, while a similar Mean Well driver is about $35–$45 . The heat sink uses high-purity aluminum with vented fins to keep 100,000-hour chips stable. It can take 20%–25% of the cost.

Traditional street lights: the “low price” comes from a simple build

Old types like high pressure sodium lamp won the market because they were cheap.

A 150 watt high pressure sodium lamp (lamp + ballast) costs about $120–$150—only one-fifth to one-sixth of a 150w led street light. In Portland, USA, data from an LED upgrade shows this: 88,871 old street lights cost $993,000 per year to maintain. The LED plan can cut about 90% of that maintenance cost.

Simple cost makeup:

Ballast: 35%–45% of total cost. Most use a basic magnetic design.

Lamp: about 15% of cost. Life is only 10,000–20,000 hours (about 1/5 of LED), so frequent changes push long-term cost up

Solar outdoor street lights: the battery eats the money

Led solar lights need no cabling, so people like them. But the upfront cost is highest. On main roads, one unit can cost $2,500–$3,500. The energy-storage battery is 30%–40% of that.

Typical parts:

Core gear (70%–75%):

Solar panel (200W mono-Si) about $200

LiFePO? battery (12V/100Ah) about $350

Smart controller $50–$80

Install cost: foundation, hoisting, and transport $500–$800 per light—much less than trenching cables for grid lights.

Home or small projects cost less. For example, a Philips 6W all-in-one solar street light sells for €50–€80 on EU sites. But these are simple units. The battery supports only 3–5 rainy days of light. They fit low-light uses.

The Impact of Technology: Smart vs. Conventional Systems

Traditional bulbs for street lights use a fixed on/off mode for a long time.

Smart dimming uses tech to change the cost math from day one to end of life.

Upfront gap and hidden value

Smart control hardware costs about 15%–20% more than basic systems.

This was proven in an LED street-light upgrade for a city client served by LinkLights., an LED project added 2,000 smart meters and a command center. The upfront spend rose, but remote fault alerts cut repair time to under 48 hours and late-night auto dimming saved power.

A Beijing comparison with 250 lights shows the same trend. Solar smart lights needed $441,000 upfront vs$419,000 for standard lights (+5.3%). But over 15 years, total cost fell from $1.21 million to about $0.49 million (a 59.3% drop).

What drives the “cost scissors”

Energy shift. Old high pressure sodium vapor lamp runs near full load all night. Smart LED uses PIR sensors and photocells to do “bright when people or cars arrive, dim when empty.” Savings can reach ~60%.

Lower upkeep. Remote monitoring plus modular parts gives early warnings and quick swaps. Maintenance cost can drop ~40%.

Installation Costs: What Goes Into Putting a led street lamp in the Ground?

Scenario-Based Installation Cost Analysis

Street light luminaire installation cost is not fixed. It depends on the site. From landscaped city arterials to simple rural lighting, the cost can vary by 10× or more.

Municipal roads: spacing and function set the cost baseline

Road class drives install cost first.

On primary city arterials, you need both high light levels and good looks. Most use dual-arm light pole at 15–20 m spacing. Cost per km: $60,000–$90,000.

On a six-lane arterial, beyond the luminaires, underground ducts, cable runs, and stronger pole bases can take 30%–40% of total cost.

By contrast, secondary streets can cost far less. With single-arm poles at 25–30 m spacing and no extra landscape add-ons, cost per km can be $30,000–$50,000.

Fixture type also changes per-light install cost:

Install only / replace only (labor + small parts, no fixture included): $300–$1,000 per light.

Furnish & Install (F&I):

LED: $800–$1,200 per light

HPS (legacy retrofit): $500–$800 per light.

With pole / foundation / cable / traffic control (new build or major rehab): well above the ranges above; estimate case by case.

Rural use in Europe/US: solar helps with off-grid needs

Baseline kit: mono-Si panel (100 W) + LiFePO4100 Ah battery + 30 W LED luminaire.

Per-light install cost: $300–$500.

Typical scenarios and ranges

| Scenario | Key drivers | Cost range |

| Primary arterial | 15–20 m spacing, smart controls | $60,000–$90,000 per km |

| Secondary street | 25–30 m spacing, single-arm | $30,000–$50,000 per km |

| Rural area | All-in-one solar, batch build | $300–$500 per light |

| Historic district / bridge | Custom fixtures, special works | Base cost +150%–300% |

Notes: Ranges depend on scope, labor, permits, and traffic control. “Install only” means labor without the fixture. “F&I” means the vendor supplies the fixture and installs it.

Energy Consumption: The Largest Long-Term Expense

Comparing Energy Efficiency Across Technologies

When city managers hesitate on a street-light upgrade, one set of numbers can break the tie.

For 855 lights over 29.7 km, one year of power use is:

250W HPS: 780,100 kWh;80W

LED: 249,000 kWh

That is a 68% cut in electricity use.

The reason has two parts: efficacy × lifespan.

LEDs make more light per unit of energy, and they last longer. So they keep creating value over time.

Efficacy and lifespan: the basics of energy use

The real strength of a light source is its system efficacy.

It equals led lumens per watt of the source × driver efficiency × fixture efficiency.

Then add lifespan to the math to get the energy cost over the full life.

Below is a key-parameter comparison for different light sources

| light source | Source efficacy (lm/W) | Driver eff. | Fixture eff. | Lifetime (hours) | System efficacy (lm/W) |

| LED | 100 | 85% | 90% | 50,000 | 76.5 |

| Fluorescent | 70 | 70% | 75% | 6,000 | 36.75 |

| Incandescent | 15 | — | 60% | 2,000 | 9.0 |

| High-pressure sodium (HPS) | 100 | 50% | 60% | 3,000 | 30 |

Typical case: assume the led street lamp runs 10 hours per day.

10-year energy use = Power × hours per day × 365 × 10.

LED (80 W): 29,200 kWh over 10 years.

HPS (250 W): 91,250 kWh over 10 years.

The gap is big—about the annual use of 32 homes.

Smart Controls: Cutting Energy Costs by 30%+

When LED street lights use smart controls, savings go beyond the light source.

LEDs give a basic ~50% cut vs. old lamps.

Add smart control, and you can save another 30%–50%.

Together, total savings can reach up to ~80%.Three smart logics: use each kWh where it matters

Smart control ends the old “full power all night” mode.

It feeds light only when needed:

Time-based dimming: lower output at set hours.

Example: drop to 30% late at night. Save ~15%–20% energy.

Light control with photocell: a light sensor tracks daylight in real time.

It turns lights on/off and trims output to match the sky.

People/vehicle sensing: with IoT data, lights brighten when cars or people arrive and dim when empty.

1.26-year payback: small spend, big return

At scale, the math gets better.In a model for a 1,000-light project, adding smart control cut power bills and reduced maintenance from single-lamp control.

The payback period was about 1.26 years.

Maintenance and replacements.

With IoT and predictive alerts, outside street lights move from “fix after fail” to “fix before fail.” Remote health checks cut the average repair time to about 24–48 hours. Crews roll fewer trucks. In many projects, maintenance cost drops by ~20%–40%.

Lifespan and when to replace.

Plan by a simple life matrix: LED module (50k–100k h), driver, battery, and pole. This tells you what to swap and when, so parts are changed on schedule, not after a blackout. It protects light levels and lowers total cost of ownership over 10–15 years.

Core component lifespans: the LED vs. legacy gap

The light source is the “heart” of a street light. Lifespans differ a lot.Street light luminaires last 50,000–100,000 hours and often run 10+ years.high pressure sodium light fixtures lasts 15,000–24,000 hours (about every 2 years you replace it).metal halide light bulb is about 10,000 hours.Incandescent is about 2,000 hours.

In real projects, the gap shows up in money:

for 100 legacy street lights, 10 years of lamp replacements can cost about $20,000.

For LED, replacements in the same period are near zero.

Energy storage and poles matter too.

In led lights solar power systems, lithium (Li-ion/LiFePO?) batteries often reach 5,000+ cycles, so they can match the LED’s life.

For poles, 304 stainless steel light pole can resist corrosion ~10 years longer than galvanized steel pole, which cuts maintenance even more.

Total Lifecycle Cost (LCC) Analysis: LED vs. Traditional vs. Solar

Case Study: LinkLights City Client — LED + Smart Controls

One of LinkLights’ city clients replaced normal street light with LinkLights’ LED and a remote monitoring system. On the pilot roads, power use fell by about 40%. Monthly bills dropped by tens of thousands of dollars. With fewer truck rolls, maintenance costs also went down. The client earned back the extra upfront cost in about 3–5 years, then kept saving for the rest of the 10–15 year life.

ROI Calculation: How Long Until Your Investment Pays Off?

When you invest in street lights, the key question is simple: how fast will the money pay back?

If you know a clear ROI method and the typical payback for each option, you can choose with confidence.

1) ROI formula: a quick way to see returns

Use this formula you can copy and reuse:

ROI = (Annual savings ÷ Initial investment) × 100%

“Annual savings” includes more than power and maintenance cuts. You can also count extra income from smart poles, such as ads or 5G leases.

Example: a smart street-light project needs $150,000 up front and saves $120,000 a year in power and O&M.

ROI = (0.87 ÷ 1.10) × 100% = 79.09%, and the payback is about 1.26 years.

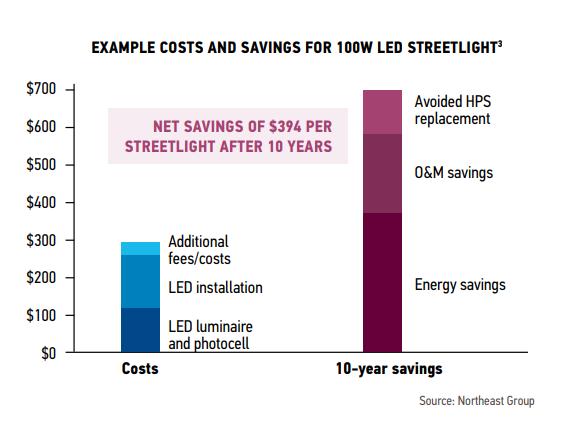

Example costs and savings for a 100W LED street light (energy, O&M, avoided HPS lamp).Source: Northeast Group.

Example costs and savings for a 100W LED street light (energy, O&M, avoided HPS lamp).Source: Northeast Group.

2) Two main paths: payback speed and best use

Different street-light plans pay back at different speeds.

Based on real cases, we group them into “fast payback” and “low-carbon for the long term.”

Below we compare the core numbers and the best scenes for each.

| Plan type | LED + smart controls | Solar street lights |

| Core advantage | Power-bill savings + extra income (ads, 5G leases, etc.) | Zero electricity cost + low-carbon |

| Typical payback | 1.26–6 years | 1.15–4 years |

| Example case | A city with 1,000 smart poles, payback in 5 years | 1,000-unit solar project, payback in 1.15 years |

| Best-fit scenarios | Urban arterials, business districts | Remote areas, new-energy demo projects |

Regional Cost Variations: Why Location Matters

High-Income vs. Emerging Markets

The global street-light market shows a clear regional split.

High-income countries and emerging markets follow very different choices and investment models because of income levels, infrastructure, and policy.

High-income markets: smart LED = high input, high return

In Europe and North America, upgrades follow a “high upfront + high savings” path.

By 2019, Europe had 50,000+ road-lighting retrofit projects, covering 500,000+ km; the Netherlands and Germany led the way.

The regional market is forecast to reach $2.8858 billion by 2030, with a 2.8% CAGR (2025–2030).

This mature market leans on smart LED tech. Buyers demand quality, stable performance, and strict lifecycle cost control.

Key driver: high labor cost.

Smart LED with sensors and IoT enables remote monitoring and automation.

It cuts patrols and maintenance visits—ideal for large areas or places with expensive labor.

Emerging markets: solar-led = low cost, policy support

In Asia, Southeast Asia, and South Asia, the picture is different.

Fast urbanization and carbon-neutral policies drive strong demand for LED and solar street lights.

Solar adoption stands out in many of these regions.

FAQ

1. Why do LED street lights cost more upfront than traditional lights?

LED street lights are usually 30%–50% more expensive than high-pressure sodium (HPS) lamps because they use advanced components such as high-efficiency LED chips, premium drivers, and aluminum heat sinks. However, they last much longer (50,000–100,000 hours), cut energy use by over 60%, and require minimal maintenance—so their lifecycle cost is much lower in the long run.

2. How much energy can LED street lights save?

In real projects, a 250W HPS lamp consumes about 780,100 kWh per year, while an 80W LED street light consumes only about 249,000 kWh—a 68% reduction. With smart dimming controls, total savings can reach up to 80%.

3. How long does it take to earn back the investment in LED street lights?

Most projects recover the higher upfront investment in 3–5 years. For example, one LinkLights city client replaced street lights with LEDs and a remote monitoring system. Power use fell by about 40%, monthly bills dropped by tens of thousands of dollars, and the city recouped costs in 3–5 years—then kept saving for the rest of the 10–15 year lifespan.

4. What extra benefits come with smart control systems?

Smart control systems add about 15%–20% to upfront costs but deliver significant value. Remote monitoring sends early fault alerts, reducing repair time to 24–48 hours and cutting truck rolls. Maintenance costs drop 20%–40%. Automated dimming at night and motion-based lighting can save an additional 30%–50% on energy bills.

5. How much lower are LED maintenance costs compared to traditional lights?

Traditional street lights have short lifespans (15,000–20,000 hours) and require frequent lamp and ballast replacements. For example, in Portland, USA, maintaining 88,871 legacy street lights cost nearly $1 million per year. Switching to LED cut those maintenance costs by about 90%.