Introduction

If you want your street lights led, garden lights led, high bay lights fixtures, or led traffic lights to work well in rain proofing, dust protection,strong cleaning, or even underwater, the most important factor isn’t just brightness or power. The key is the IP Rating (Ingress Protection, IEC 60529).

This guide—built from top manufacturers and real-world use—gives clear and practical advice for buyers, engineers, and maintenance teams. It helps you understand what to look for so you can make the right choice quickly and with confidence.

What Is an IP Rating?

The IP Rating (Ingress Protection Rating), also called the International Protection Rating, is a safety code from the international standard IEC 60529. It explains how well a device’s case can stop dust, solid objects, touch, and water from getting inside.

The format is simple: “IP” + two numbers.

The first number shows protection against solids, like dust or other solid objects.

The second number shows protection against liquids, meaning how well the device resists water.

IP rating explained in simple terms

For outdoor led street lamps (like outdoor street lights led, tunnel led lights, and mining lamps), the IP rating shows how reliable they are and how long they will last in different places:

Ip65 rating: Fully dustproof and safe from low-pressure water jets. Good for most outdoor led lighting.

Ip66 rating: Dustproof and safe from strong water jets. Works well in heavy rain or sandstorms.

Ip67 rating: Can handle short-term water immersion, such as heavy rain or flooded roads.

Ip68 rating: Can stay underwater for a long time. Often used in fountains, pools, or underwater lights.

Ip69k rating: Can resist hot, high-pressure water jets. Great for areas with frequent cleaning, like car washes or food factories.

Ip67 rating chart for LED lights

General Outdoor Roadway Lighting (IP65)

Typical Environments: Urban roads, rural highways, parking lots, public squares, and campus pathways.

Installation Conditions: Fixtures must face downward with a tilt angle ≤15° to minimize direct water ingress.

Typical Luminaires: Outside street lights, searchlights, downward-facing wall washers, floodlights led.

If a light has seams within 15°of the top, choose an IP66 rated fixture to stop water from getting inside. For roadway and led parking lot light fixtures, which often run at higher power, IP65 provides dust proof protection and better heat control. This helps extend service life and answers the common question: do led lights last longer? The answer is yes—when designed with the right IP rating.

Best IP rating for outdoor landscape lights

Typical Environments: Building facades, bridges, trees, sculptures, and other outdoor decorative lighting.

Installation Conditions:lights installed upward-facing or with a tilt angle >15°; also suitable for semi-exposed or embedded applications such as facade wall washing or curtain-wall linear lighting.

Typical Luminaires: Surface-mounted wall washers, linear lights, pixel/point sources, architectural floodlights.

IP66 gives strong protection from heavy rain (rain define) and is dust resistan, making it good for long-term outdoor use.It is ideal for lights that need frequent cleaning or are exposed to harsh weather, helping them stay reliable for many years.

IP67 for in-ground and waterfront lighting

Typical Environments: Outdoor ground areas prone to temporary water accumulation (≤1m) or installations near waterfronts.

Typical Applications: Garden beds, pedestrian pathways, stairways, railings, and embedded architectural facades.

Typical Luminaires: Linear lights, pixel/point sources, in-ground uplights, embedded wall washers.

IP67 protects against short-term water immersion and damp places, but it is not for permanent underwater use.For water deeper than 1 meter or long-term underwater use, IP68 is required.In underwater or closed setups, good heat control is very important. Poor heat dissipation can cause the light to fail early.

IP68 waterproof underwater lights

Typical Environments: Long-term underwater applications or installations deeper than 1m.

Typical Applications: Fountains, swimming pools, artificial lakes, and underwater landscape lighting.

Led street lighting fixtures must be fully waterproof. and able to work safely while staying underwater for a long time.Strong design and good heat control are needed to handle water pressure and heat. This shows the quality of the manufacturer’s engineering.

Why the Same IP Rating Can Perform Differently

Ingress protection testing:

IP65 → Low-pressure water jet for 3 minutes.

IP66 → High-pressure water jet for 3 minutes.

IP67 → 1 meter immersion for 30 minutes.

Reality:

led street lights outdoor may face:

Constant UV rays, blowing dust, acid rain, and salt spray for many years.

Daily changes in temperature, where parts expand and shrink, putting stress on seals until they weaken.Passing an ip testing in a lab does not always mean the light will stay waterproof outdoors over time.

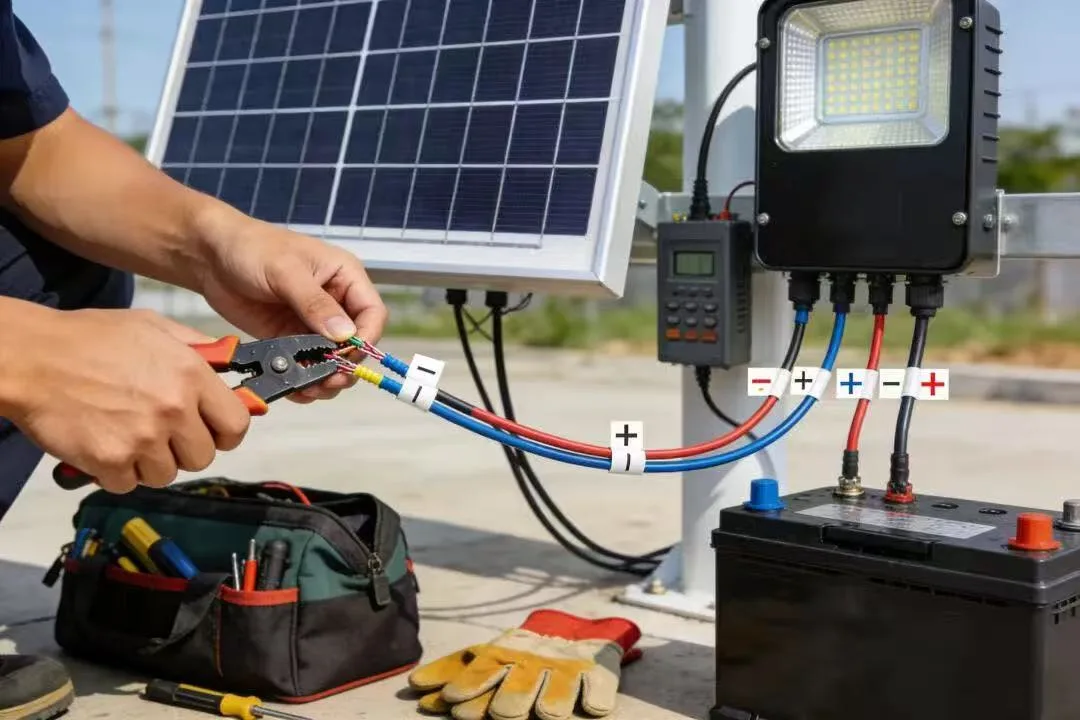

Sealing Design Differences

Structural Sealing:

Uses silicone gaskets, PG cable glands, and screw pressure. This needs very precise parts and high assembly quality to keep water out.

Potting/Encapsulation Sealing:

Fills spaces and covers electronics with resin or silicone. It works at first, but if the material cracks, shrinks, or ages, the protection is lost for good.

Two lights may both have an waterproof rating ip67, but their long-term durability can be very different, depending on whether they use structural sealing or potting.

Material Aging and Environmental Resistance

UV Exposure:

Long sunlight makes plastic housings brittle, causes coatings to peel, and makes rubber gaskets lose flexibility.

Temperature Extremes:

In summer, light surfaces can reach about 60 °C. In winter, freezing temperatures can make plastic brittle.

Different materials (like glass and aluminum) expand and shrink at different rates. Over many hot-cold cycles, tiny gaps can form at the joints.These problems do not appear in short IP tests but often show up after 1–2 years of outdoor use.

Pressure Differentials and the “Breathing Effect”

When outside temperature drops fast, the inside of the light forms low pressure. This pulls in moist air through tiny gaps.

When the temperature goes back up, the air is pushed out, but water drops stay inside. Over time, this happens again and again, leading to moisture buildup.

This is why many in-ground or landscape lights, even with an IP67 rating, often fog up or show water inside after real use.

Factors Beyond the IP Code

Corrosion Resistance:

Lights on marine docks or in chemical plants need extra tests for salt spray or chemical resistance (such as WF2 rating) in addition to IP.

Impact Resistance:

The IK rating shows how well the light can handle hits or vandalism.

Installation & Maintenance:

If a light is opened and the gasket is not put back right, the ip rating waterproof is lost.Bad cable endings or loose connectors can also let water in.

Ip ratings alone do not cover corrosion, impact, or installation quality, and these can greatly affect long-term performance.

Conclusion:

The IP code only shows test results for dust and water. Real durability depends on sealing design, material quality, heat and pressure control, corrosion resistance, and installation. This is why two lights with the same IP rating can perform very differently over time.

IP65 vs IP66 vs IP67 vs IP68: How to Decide

Cost Factors

As the IP rating goes up, the design gets more complex, the molds need higher precision, and the materials and process control must be better.

IP65/66: Usually reached with gaskets and screw pressure sealing.

IP67/68: Often needs potting compounds, multi-layer seals, or one-piece molded housings, which make production much more expensive.

Risk Assessment

Normal areas like roads, plazas, and parking lots → IP65 is enough.

Places with heavy rain, strong wind, or frequent washing → IP66 is safer

Flood-prone areas or places with standing water → IP67 or higher is required.

Selection Rule: Do not always chase the highest IP rating. The goal is to balance good protection with reasonable cost.

Maintenance Style

Routine Cleaning

For led bulbs street parking lot lights or commercial solar pathway lights, IP65 is enough to handle normal weather and dust.

High-Pressure Washing

For tunnels, bridges, and industrial building exteriors that are often washed with strong water jets → IP66 is the minimum.

For food plants or car washes where hot, high-pressure cleaning is common → IP69K is required.

Temporary Flooding or Water Exposure

For in-ground uplights, plaza stair lights, and garden bed fixtures → IP67 is needed.

Permanent Submersion

For fountains, swimming pools, or underwater landscape lights → IP68 is needed. The maker must confirm the exact depth and time the light can stay underwater.

Conclusion: How you clean and maintain the light decides the IP rating—especially for strong washing or flooding.

Project Lifespan Goals

Short-Term Installations

For temporary events or short projects, IP65/66 is usually enough.

Long-Term Installations (10+ years)

Over time, sunlight, heat, cold, and expansion can damage sealing parts. This can make the light less safe.

Coastal or Chemical Environments

In these places, the IP number alone is not enough. Corrosion resistance is key—such as WF2 salt-spray tests, anti-corrosion coatings, and marine-grade stainless steel screws.

Even an IP66 light can fail early if screws or coatings are not corrosion-resistant.

The longer the light is meant to last, the more you must check the materials and corrosion resistance—not just the IP rating.

Supplier Capability

Consistency and Quality Control

Many makers can build one product that passes an IP test, but keeping the same sealing quality in mass production is harder. Key points include:

Same gasket hardness and size accuracy.

Consistent potting or encapsulation.

Reliable breather valves in every batch.

R&D and Verification

Can the supplier give test reports for salt spray, UV aging, thermal cycling, and IK impact?

Can they adjust IP68 depth ratings (like 3m, 5m, or 10m) for project needs?

Summary: Higher IP ratings are not just about adding more material. They show the supplier’s design strength, process control, and quality checks.

Procurement & Acceptance Checklist

When buying LED outdoor lights, check they meet IEC 60529 and ask for third-party IP test reports. Choose the right IP level for the job—IP66/69K for strong water jets, IP67/68 for underwater use (depth and time must be clear). Look at sealing parts such as breather valves, gaskets, and cable glands. Make sure the light resists corrosion, with salt spray tests, strong coatings, and stainless steel like 316L. Ask for extra safety tests: surge, impact, UV, flame, and insulation. Follow install guides to keep the seal safe. Last, check the warranty and real project cases for proof of reliability.

Common Myths & Corrections

Myth 1: IP68 is universal → Reality: Only for the depth/time tested.

Myth 2: IP number is all that matters → Reality: Corrosion, UV, and mechanical impact resistance are just as important.

Myth 3: Installation doesn’t affect IP → Reality: Incorrect sealing during installation will compromise protection.

Myth 4: Higher IP is always better → Reality: Match to environment & maintenance style.

Tangible Benefits for Buyers, Engineers & Maintenance Teams

Fewer failures & ingress incidents: Correct IP + solid design = less downtime.

Longer lifespan & lower TCO: Optimized IP reduces replacements and repairs.

Faster procurement: Use the checklist to align with suppliers and speed decisions.

Compliance confidence: Meet IEC 60529 and local electrical codes.

9. FAQ

Q1: Is IP65 enough for outdoor LED lights?

Yes, for most roads/parks. Upgrade to IP66 in storm/coastal or washdown areas.

Q2: Difference between IP66 and IP65?

Both have “6” dust protection; IP66 resists stronger water jets.

Q3: Pool/fountain lighting?

Choose IP68, with confirmed immersion specs; near-waterline (not submerged) can use IP67.

Q4: Why does one IP66 fail sooner than another?

Differences in sealing, assembly, and materials—plus installation quality—affect long-term performance.

Q5: Is IP69K the highest rating?

For hot/high-pressure spray, yes—but immersion resistance is covered under IPX7/8.

Conclusion

IP Ratings are the first gateway for selecting outdoor and harsh-environment lighting—but they’re not the whole story. Focus on environment → maintenance → cost → compliance to choose the right IP level, while also considering sealing design, materials, installation quality, and certifications. This is how you build an LED lighting system that’s both reliable and cost-effective.