Introdution

In big places like warehouses, factories, sports centers, and large stores, lamps with good lighting is very important for safety, work speed, and getting jobs done well.

In the last ten years, types of high bay lights such as LED fixtures have become the top choice lighting supply because led lights save energy, last a long time, and give better light than older HID or led fluorescent lighting fixtures. But to get these benefits, you must pick and set them up the right way. Different areas need different brightness, light spread, and run times, so one fixed setup will not work for all.

This 2025 LED High Bay Lights Buying Guide will help you choose the right type, brightness, and beam angle, check the most important features, follow good setup steps, and work out costs and savings—so your new lights give value for many years.What Are led high-bay lights?

What Are led high-bay lights?

High bay led lights are high bay light bulbs bright enough for places with ceilings higher than 15 feet (4.5 meters). They work well as led in ceiling lights, spreading light evenly over large, open spaces without dark spots. This makes them a good choice for warehouses—especially when using high bay panel lights for warehouses. Knowing what they are is just the first step—next, we will look at why switching to LED high bay lights is a smart choice for your building.

Why Switch to high bay led lighting?

Upgrading to led high-bay lights is no longer just a trend—it’s a strategic business move with measurable benefits:

Power Consumption Comparison

A typical 400w metal halide high bay lights actually uses about 452W of power because of the lamp and led street light ballast. In most factory or warehouse lighting upgrades, you can replace a 400W MH with a 100–150 watt high bay light and get the same or even better brightness.

Energy Savings Potential (50–75%)

The energy savings are calculated using the formula:

Savings (%) = (Original Wattage – led bulb wattage) ÷ Original Wattage × 100.

For example, replacing a 452W MH with a 120W LED results in a reduction of around 73%. Across various wattage replacement scenarios, savings typically range from 50% to 75%

Lifespan, Luminous Efficacy, CRI, and CCT

Lifespan: Metal halide high bay lights usually last 10,000–20,000 hours, while good LED fixtures can run over 50,000 hours (L70), proven by ANSI and LM-80 tests.

Annual Energy Savings Examples

Annual energy savings can be calculated with:

Annual kWh Saved = (Original Wattage –led street lamp wattage) × Daily Operating Hours × 365 ÷ 1000.For instance:

Warehouse (12 hours/day): ~1,314–1,542 kWh saved per fixture annually ($131–$308 at $0.10–$0.20/kWh).

Manufacturing Facility (16 hours/day): ~2,336–4,672 kWh saved per fixture annually ($280–$934 at $0.12–$0.20/kWh).

Cold Storage (24/7): ~2,645–3,085 kWh saved per fixture annually, with the added benefit of lower cooling loads, as confirmed by DOE and ASHRAE research.

Bottom line: Switching from metal halide fixture to high-efficiency LED lighting reduces operational costs, minimizes maintenance, and delivers superior lighting quality—all while aligning with energy efficiency standards and sustainability goals.To fully realize these benefits, selecting the right type of led high bay light for your application is critical.

Types of high bay light fixtures

Not all led high bay light fixtures are the same. The best choice depends on your high bay led lighting ceiling height, building layout, and environment. Picking the wrong type can cause uneven light, waste energy, or require expensive changes later. Below is a simple guide to the main types, along with a quick high bay light layout chart to help you choose.

How to choose the right type:

Ceiling Height

4.5–6 m → linear led high bay light or vapor tight led high bay light types for focused coverage.

6–12 m → high bay ufo light or linear for general industrial/retail spaces.

12 m+ → High-output UFO or high temperature led high bay light for extreme conditions.

Space Layout

Wide open space → ufo high bay lighting type.

Narrow aisles / shelving → Linear type.

Environmental Conditions

High humidity/dust → Vapor-tight IP65+.

Extreme heat → High-temperature model.

Food-grade hygiene → NSF-rated.

Hazardous location → Explosion-proof (Class I Div 2).

Control Requirements

Energy savings / automation → Integrated sensor model.

| Type | Shape / Protection | Best For | Advantages | Market Insight |

| UFO High Bay Lights | Compact round “UFO” design, single mounting point; 90°–120° beam angles | Warehouses, sports arenas, gyms, large workshops | Easy installation, minimal glare with correct lens, suitable for new builds & retrofits | 60%+ adoption in North American warehouses due to versatility & upgrade ease |

| Linear High Bay Lights | Rectangular housing for broad, linear coverage | Aisles, production lines, racked storage | Reduces shelf shadows, supports continuous row mounting | ~45% share in large-format retail/logistics spaces |

| Vapor-Tight / Harsh Environment | IP65+ sealed housing resists moisture, dust, chemicals | Food processing, car washes, marine facilities, outdoor canopies | Maintains lumen output & lifespan in harsh conditions | Rising demand in food-grade sectors under stricter hygiene rules |

| With Integrated Sensors | Built-in motion detection & daylight harvesting | Storage areas, multipurpose halls | Up to 60% energy savings, reduced maintenance, longer LED life | Growing adoption in energy-conscious & LEED-certified buildings |

| High-Temperature | Designed for ambient temps up to 80°C | Steel plants, foundries, glass manufacturing | Maintains lumen stability under heat stress | Niche but critical for extreme-heat industries |

| Food-Grade (NSF) | NSF or equivalent food-safe certification | Food/beverage production, pharma clean rooms | Hygienic, corrosion-resistant, meets strict standards | Increasing use in food & pharma sectors |

| Explosion-Proof (Class I Div 2) | Built for hazardous environments with flammable vapors/dust | Oil refineries, chemical plants, grain handling | Safety compliance, robust build, prevents ignition | Vital in hazardous industrial settings |

Key Specifications to Consider

Before you buy, check these performance factors to make sure the light fits your needs:

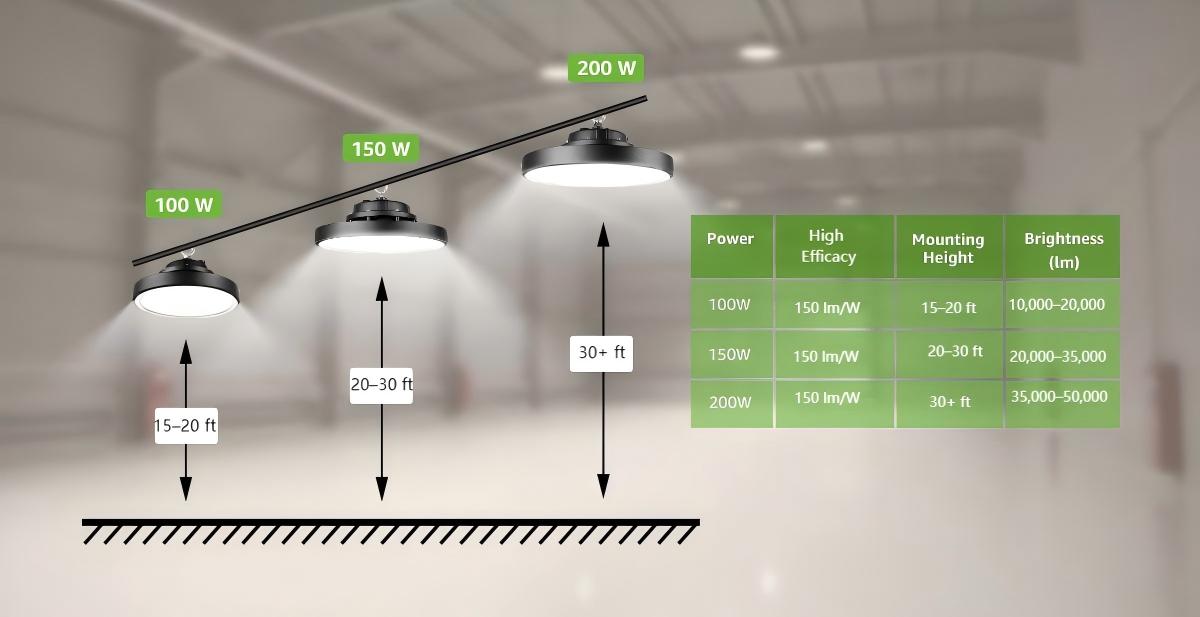

Lumen Output

The luminous flux (lumens) of LED high bay lights must match the installation height, because the higher the height, the more obvious the light attenuation is, and higher lumens are required to achieve appropriate illumination on the ground.

15–20 ft: 10,000–20,000 lumens

20–30 ft: 20,000–35,000 lumens

30+ ft: 35,000–50,000+ lumens

Selecting the right lumen range ensures optimal visibility, safety, and energy efficiency without over- or under-lighting the space.

Wattage & Efficacy

Luminous efficacy (lm/W) shows how much light you get for each watt of power. Many buyers look only at led street light wattage and forget lamp efficacy, which can lead to buying low-efficiency lights that use more electricity. Choosing high-efficacy lights (≥130 lm/W) gives the same brightness with less power, lowering energy bills while keeping good performance.

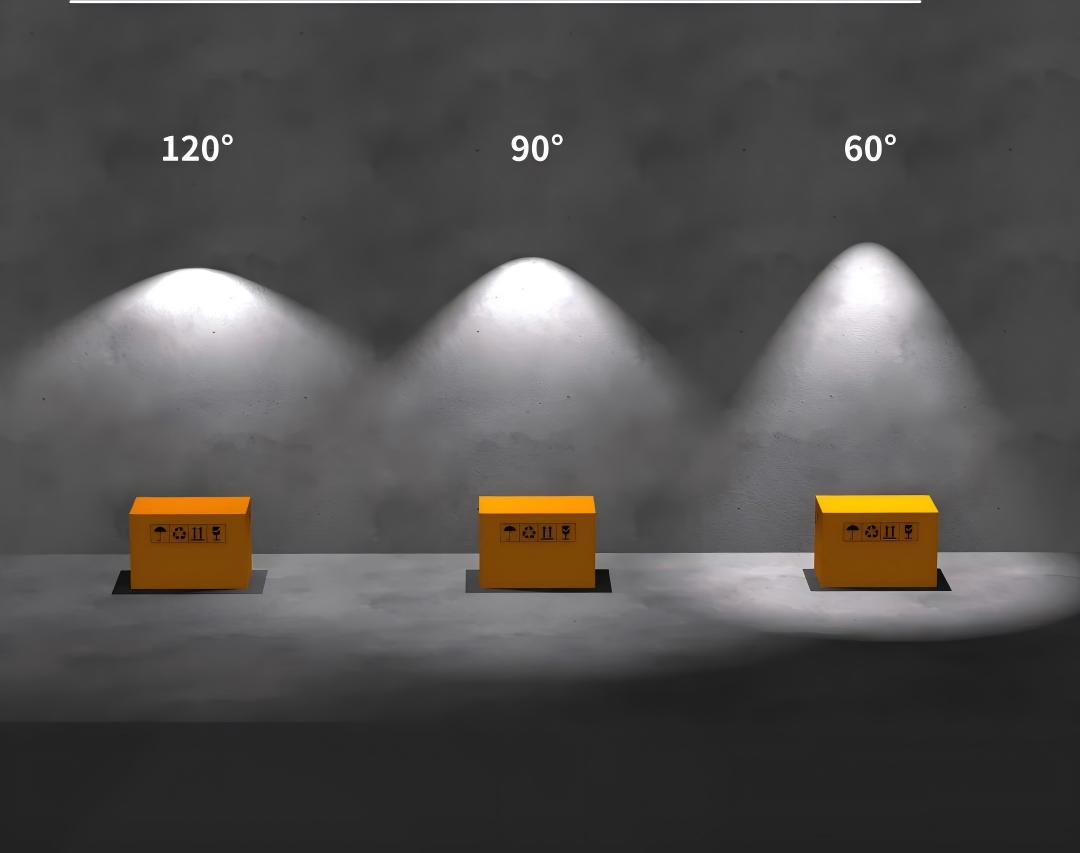

High bay light beam angle

Choose the beam angle based on high bay lighting mounting height and high bay led light spacing for the best light spread. A60°beam works well for tall bays, focusing light to cut waste and increase the high bay light coverage area at floor level. A90°beam fits mid-height bays, giving a balanced spread without too much spill. A120°beam suits led low bays, covering wide areas for even lighting. This way, the design meets high-, mid-, and low-mount needs effectively.

Color Rendering Index (CRI)

In industrial and mining work, seeing colors correctly is key—whether checking equipment, controlling product quality, or doing daily tasks, you need clear and accurate visuals. The Color Rendering Index (CRI) shows how well a light shows true colors, and different CRI levels fit different uses.

CRI70+: Good for general industrial led lighting, such as warehouses, logistics, and basic manufacturing. Gives enough brightness and basic color recognition.

CRI80–90: Best for work needing higher color accuracy, like textiles, painting, printing, food sorting, and electronics assembly. Shows richer colors and clearer details.

CRI≥90: Suited for high-end displays and precision work, like medical checks and art galleries. Colors look almost the same as in natural led, showing the best quality and texture.

Color Temperature (CCT)

4000K: Neutral white—balanced visibility and comfort.

5000K: Cool white—enhanced clarity for task-oriented work.

IP Rating

IP65+: For dusty or wet areas.

IP40–54: For clean, dry indoor spaces.

With these specifications in mind, the next step is to translate them into a practical lighting layout.

High bay lighting layout and high bay light spacing Guidelines

The high bay light fixture spacing should be determined by considering factors such as the specific application, high bay light wattage, and beam angle. Correct spacing ensures even illumination without causing over-lighting or leaving dark spots. As a general guideline, when the mounting height for high bay lights are 15–20 ft, maintain a spacing of 12–16 ft; for heights of 25–30 ft, use 16–24 ft spacing; and for heights of 30–40 ft, space fixtures 20–28 ft apart.

Pro Tip: Use photometric simulation software or request a lighting layout from your supplier to achieve optimal uniformity and compliance with standards such as IES RP-8 or EN 12464.

Installation & Mounting Tips

High bay lighting mounting options:

UFO led high bay lights – hook, pendant, or surface mount.

Linear led high bay lights – chain, cable suspension, or surface mount.

Safety tip: Check ceiling load capacity and hire certified electricians.

Smart Controls & Dimming

Adding smart lighting control can make high bay lighting more efficient and flexible.

0–10V dimming lets you adjust brightness for tasks or when people are present. Motion sensors turn lights on only when needed. Daylight harvesting dims lights when there is enough natural light. Wireless control, using ZigBee, Bluetooth Mesh, or DALI, allows central management. These features cut energy use, make fixtures last longer, and give lighting that adapts to work patterns.

Cost Breakdown and ROI

High bays lighting cost more at first than old style street lights, but their total cost over time is much lower. Switching to energy efficient light fixtures can save 50–75% on power bills and cut maintenance costs by reducing replacements and labor. DLC-listed fixtures may also get utility rebates, which can shorten payback to just 1–3 years, depending on use and energy rates. Beyond cost, here are answers to common buyer questions.

FAQs:

Q1: How many high bay lights do I need?

A: Divide your total lux target by the lumen output per fixture, then apply proper spacing guidelines.

Q2: Are LEDs suitable for cold storage?

A: Yes—LEDs excel in low temperatures and outperform fluorescent or HID in such environments.

Q3: Can I dim all LED high bays?

A: Only those with dimmable drivers or control interfaces support dimming.

Q4: What’s the ideal height for high bay installation?

A: Typically 15 ft and above; adjust lumen output for higher ceilings.

Final Thoughts: Choosing the Best LED High Bay Lights in 2025

Selecting the right LED high bay lighting is a strategic investment in safety, productivity, and energy efficiency. By understanding fixture types, technical specifications, installation best practices, and ROI considerations, you can choose a solution that meets both current and future needs.

Before making your decision:

Define lighting goals (lux levels, efficiency targets).

Assess environmental factors (temperature, humidity).

Select reputable suppliers with certifications (DLC, UL, ETL).

Plan for future upgrades with smart control integration.

Lighting is more than a utility—it’s a critical component of operational success. Make the switch to LED high bay lights in 2025 and illuminate your facility the smart way.