Introduction:An Engineering-Level Guide for Street and Road Lighting Projects

In modern public and led street lighting, performance is not about watts or lumens. It is about light distribution. Light distribution decides if a outdoor street light creates a safe, comfortable, and well-controlled lighted street, especially in outdoor street light and road light LED applications.Two LED street lights can have the same lumen rating and still perform very differently. This is because of optics, mounting height, and installation. For this reason, understanding light distribution is a basic engineering requirement for street, road, and outdoor public lighting projects. This article explains LED light distribution from a system-level view, based on real projects. It does not compare products. It helps planners, engineers, and buyers make decisions that are clear, reliable, and easy to verify.

Understanding LED light distribution in Street and Road Lighting

Light distribution describes how a luminaire spreads light. It shows where the light goes, how far it reaches, and how evenly it covers the ground. In street and road lighting, light distribution is a core engineering factor. It decides whether a lighting system works as intended. Light distribution affects street light illumination, lighting uniformity, glare for road users, light spill outside the roadway, and pole spacing. Because of this, light distribution often matters more than peak lumen output. A led street light can look very bright but still fail to light the road. A lower-lumen fixture with good optical control can deliver better usable light, more even coverage, less glare, and higher visual comfort while using less energy.

Why Light Distribution Matters More Than Brightness

In outdoor lighting, the goal is not to make the road as bright as possible. The goal is to provide clear, even, and comfortable light only where it is needed. For example

Two 70 W outdoor street lights were tested.

Both had a luminous flux of approximately 7,000 lm.

One used a large Type-I lens with a narrow beam.

The other used a small multi-lens array with a wider beam.

Both luminaires were installed at a mounting height of 10 m, with a pole spacing of 35 m, lighting a 12 m wide roadway.

Testing was conducted in accordance with Thai roadway lighting standards.

Results:

| Parameter | Large Lens | Small Lens Array | Standard Requirement |

| Average illuminance | 18 lx | 22 lx | ≥ 20 lx |

| Illuminance uniformity | 0.38 | 0.52 | ≥ 0.4 |

| Longitudinal luminance uniformity | 0.65 | 0.81 | ≥ 0.7 |

The small lens array, with its wider light distribution, provided better overlap between adjacent poles. This reduced dark zones beneath the luminaires and met both safety and visual comfort requirements.The large lens, with its narrower distribution, showed uneven lighting and higher glare.

Engineering Standards That Prioritize Light Distribution

Street and road lighting performance is evaluated using standards from the Illuminating Engineering Society (IES) and regional systems such as EN 13201.

These standards do not define lighting quality by fixture shape, wattage, or raw lumen value.

Instead, they focus on:

How light is distributed on the road surface

Uniformity between bright and dark zones

Glare limits for road users

Whether the distribution fits the road type and environment

In these systems, light distribution is a main design requirement.

Lumen output only matters when combined with proper optical control.

Why Light Distribution Matters More Than Lumens

Many people think that higher lumens always mean better outdoor street lighting.

In real projects, this belief often causes problems. Roads can look uneven, glare complaints increase, and energy is wasted.

Tests on real roads and lighting simulations show the same result again and again. Two LED street lights with almost the same lumen rating can produce very different light on the ground. Even when they are installed at the same height and with the same pole spacing, usable road light can differ by 20–40% or more. This difference is not caused by LED chips or electrical power. It is mainly caused by optical design and light distribution.

IES LM-79 photometric tests confirm this effect. Lights with the same total lumen output can send light in very different directions. When these light patterns are used in Dialux or AGi32 simulations, the isolux maps change clearly. Average light levels, minimum light levels, and uniformity can all change a lot, even though the lumen values are the same.

These differences come from optical design choices. They include beam angle, cutoff and shielding, how much light goes forward or to the sides, and how the distribution works with mounting height. Poor optical control often sends too much light outside the road. This increases glare and reduces comfort without improving visibility.

Because of this, good street lighting does not depend on higher power or more lumens. It depends on precise optical control and the right light distribution. Simply adding more lumens usually increases energy use and discomfort, with little real benefit.

In public and roadway lighting, the goal is not maximum brightness.

The goal is controlled, even, and comfortable light. This approach follows modern lighting practice defined in standards such as IES RP-8 and EN 13201.

The Five Standard lighting distribution types

Most LED street and road lighting projects use one of five standard lighting distribution types.

These types describe how light spreads forward and sideways from the pole.

Type I — Linear Distribution for Paths and Narrow Streets

Type I creates a long, narrow light pattern.

The light spreads evenly along the length of the fixture.

This type is usually used when lights are installed along the center of a path.

Common uses include walkways, narrow residential streets, and pathway lighting.

Type I works well for straight, narrow areas.

However, it is not suitable for wide roads because it often leaves dark areas near the edges.

Type II — Forward Distribution for Secondary Roads

Type II spreads light forward and slightly to the sides.

It covers more width than Type I while still keeping good direction control.

This distribution is often used on secondary roads, wider pedestrian paths, and access roads.

It works well when lights are installed on one side of the road.

Type II provides good forward reach while limiting light spill beyond the curb.

Type III — The Most Common Distribution for Road Lighting

Type III is the most widely used light distribution in street lighting.

It provides strong forward light and wide side coverage.

This makes it suitable for outdoor street and collector roads.

Type III fixtures are commonly installed at heights of about 6 to 10 meters.

At these heights, poles can be spaced farther apart while still maintaining even lighting.

Many cities prefer Type III because it offers a good balance of coverage, efficiency, and glare control when properly designed.

Type IV — Perimeter and Edge-Controlled Distribution

Type IV directs most of the light forward and very little backward.

It is designed to reduce light shining behind the pole.

This type is often used near property lines or road edges.

Common applications include perimeter roads, areas next to homes, and facility boundaries.

Type IV is especially useful where light spill and glare must be kept to a minimum.

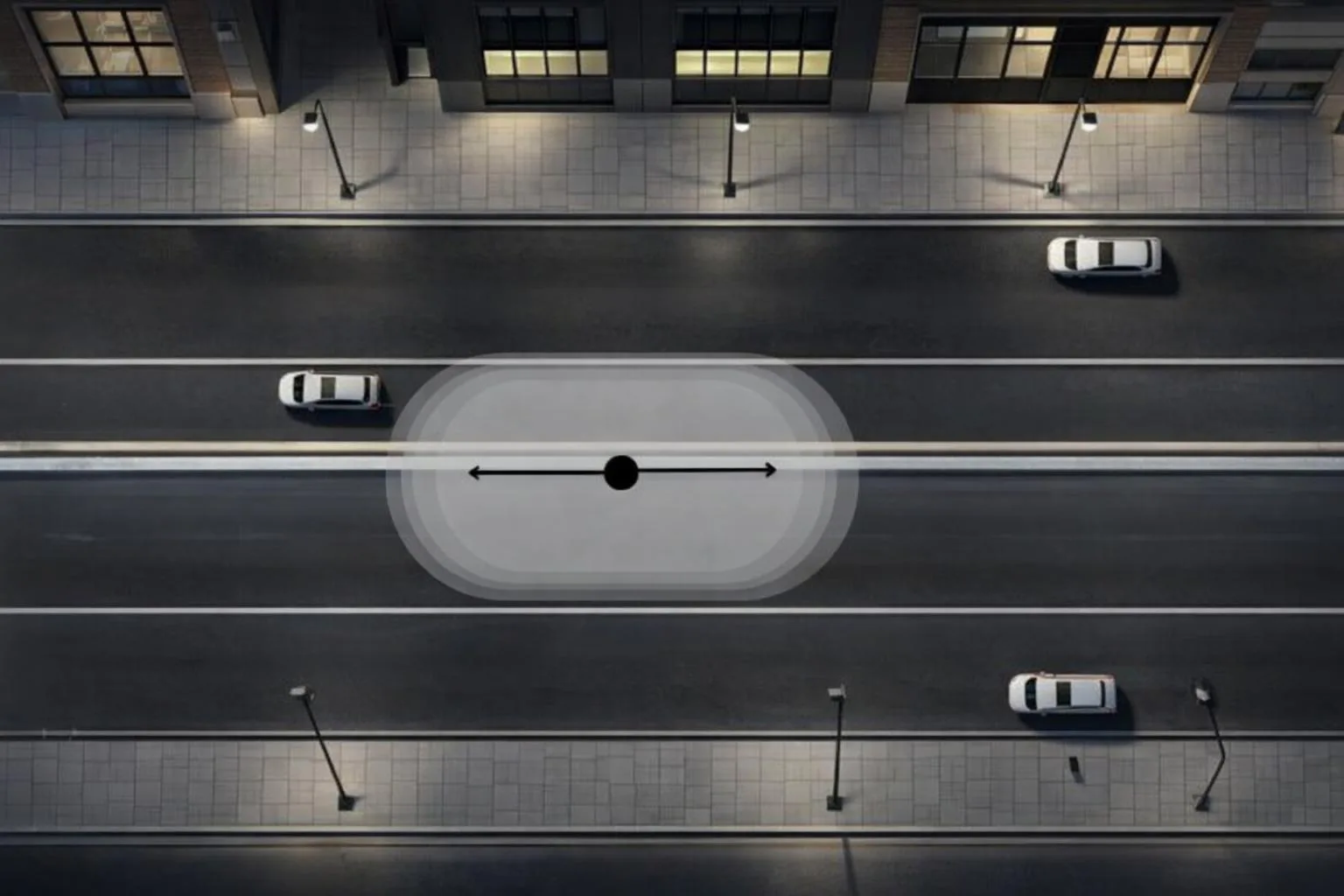

Type V — Symmetric Distribution for Large Open Areas

Type V spreads light evenly in all directions around the pole.

The illuminated area is usually circular or square.

This distribution is commonly used in large intersections, plazas, and wide highway areas.

It provides broad coverage but is not efficient for narrow streets.

On narrow roads, much of the light falls outside the target area and is wasted.

Light Distribution, Street Light Spacing, and Glare Control

Street light spacing is not random.

It depends on light distribution, mounting height, and road shape.

When asking how far apart are street lights should be, the engineering answer is simple:

it depends on the distribution type.

In general:

Narrow light distributions need poles placed closer together

Wider light distributions allow more space between poles

Higher mounting heights require wider and better-controlled beam patterns

Ignoring these relationships often causes problems.

These include too much light, glare, or dark gaps between fixtures.

Proper spacing starts with choosing the right light distribution.

It should then be confirmed using photometric analysis.

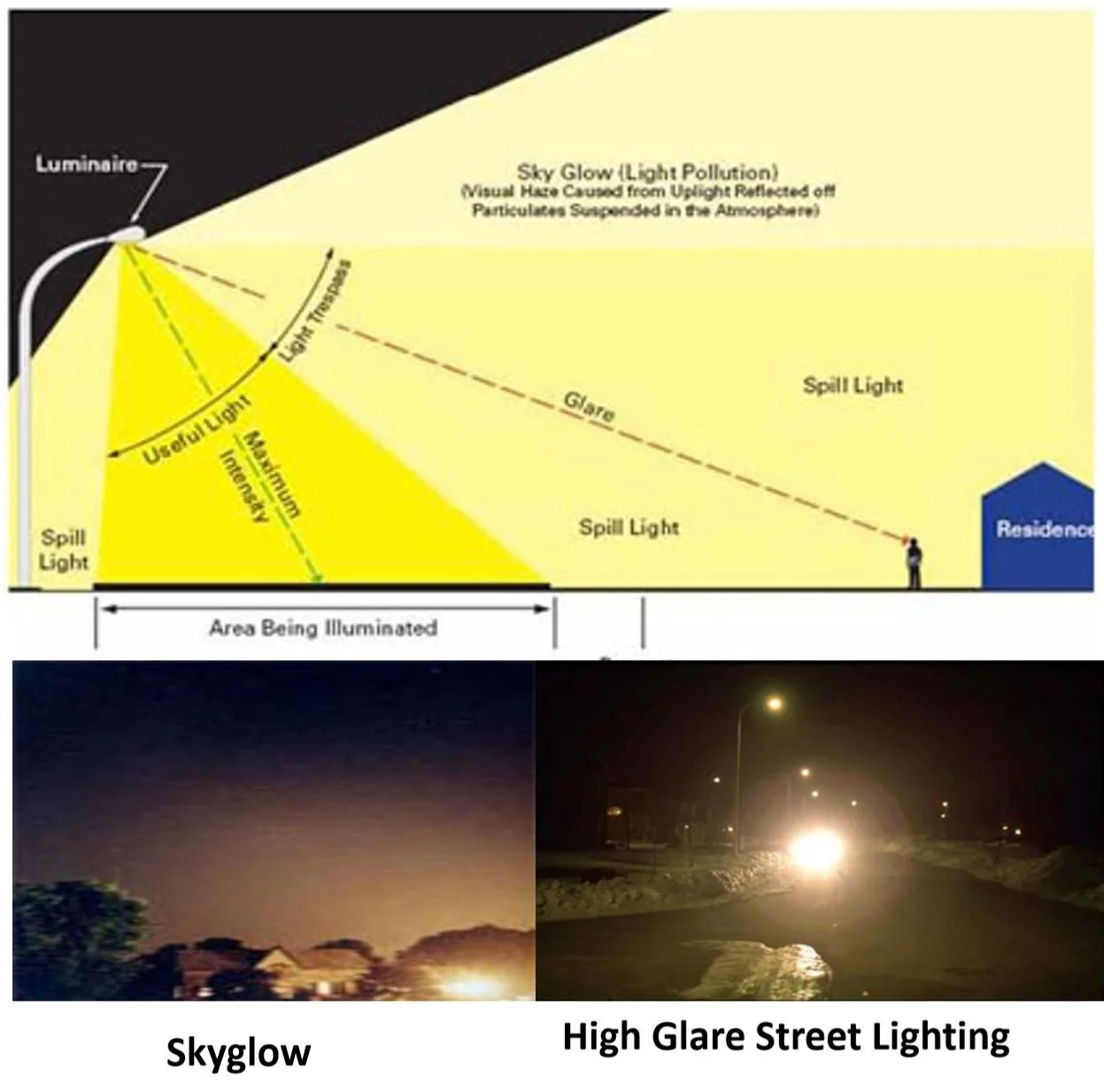

Glare is one of the most common problems in public lighting.

It reduces visibility, causes discomfort, and can affect road safety.

Good glare control depends on:

Proper optical cutoff angles

Lens shape and internal shielding

Control of high-angle light output

Professional types of street lights include these features by design.

This is especially important for led highway lights and high-speed roads.

Street Light Size, Optics, and Modern Distribution Concepts

Questions like “how big is a street light” are often misunderstood.

They are usually seen as questions about physical size only.

From an engineering view, size is more about optics and heat control than outer dimensions.

A larger luminaire can allow:

Better optical control

Better heat dissipation

More even light output across the LED array

However, a larger fixture does not always mean better performance.

Good lighting depends on matching the optics, light distribution, and mounting height to the application.

Modern designs, such as modular or hexagonal led lighting layouts, are used to improve light control and efficiency.Some “nature LED” designs focus on visual comfort.

In real projects, visual comfort depends more on even lighting and glare control than on color temperature alone.

Even as street light designs change, one rule stays the same:

light distribution is what determines performance.

Choosing the Right LED Light Distribution: Engineering Takeaways

Selecting the right light distribution starts with understanding where the light will be used.

In general:

Residential streets focus on visual comfort and even lighting

Arterial roads need strong forward visibility and consistent coverage

Highways require long reach with strict glare control

Public spaces need balanced, and often symmetric, illumination

street lgiht should always be evaluated as part of a full system.

This includes pole height, pole spacing, and surrounding conditions.

Distribution choice should not rely on catalog descriptions alone.

It must be confirmed using objective and measurable methods.

Verifying Distribution Performance in Professional Projects

In public lighting projects related to safety, distribution assumptions must be verified.

This is usually done through:

Lighting simulations using manufacturer IES files

Review of LM-79 test reports to confirm light output, power input, and light distribution

On-site light level measurements after installation using calibrated tools

This process helps ensure that the design works as intended in real conditions.

It also reduces the risk of glare complaints, dark areas, or expensive redesign work.

Final Engineering Takeaways

LED street lighting is not about maximum brightness.

It is about proper light distribution.

Good distribution design:

Improves visibility without increasing power use

Reduces glare and unwanted light spill

Allows better pole spacing and fewer fixtures

Delivers consistent and predictable results

By basing decisions on recognized standards, measured data, and verified methods, engineers can avoid relying on marketing claims alone.

In professional street and road lighting projects, focusing on distribution first is what leads to reliable, long-lasting infrastructure instead of avoidable redesigns.

FAQ

Why is light distribution more important than lumen output in street lighting?

Because lumen output only tells how much light a fixture produces, not where that light goes. Light distribution determines how evenly light reaches the road surface, how well glare is controlled, and how much light is wasted outside the roadway. Two fixtures with the same lumen rating can deliver very different road lighting performance due to optical design and distribution.

Can two LED street lights with the same wattage and lumens perform differently?

Yes. Real-world tests and lighting simulations often show 20–40% or more difference in usable ground illuminance between fixtures with similar wattage and lumen values. These differences are mainly caused by optical distribution, beam shape, cutoff design, and how the light interacts with mounting height and pole spacing.

Which light distribution type is most commonly used for road lighting?

Type III is the most widely used distribution for street and road lighting. It provides strong forward throw and wide lateral coverage, making it suitable for most urban streets and collector roads. When properly designed, it offers a good balance between coverage, efficiency, and glare control.

How does light distribution affect street light spacing?

Light distribution directly affects how far apart poles can be placed. Narrow distributions require closer spacing to avoid dark gaps, while wider and well-controlled distributions allow larger spacing. Proper spacing should always be verified using photometric simulations rather than estimated from wattage alone.

Does increasing wattage help fix uneven or poor lighting?

Usually not. Increasing wattage or lumen output without correcting light distribution often increases glare, energy consumption, and light spill, without improving visibility. Poor lighting performance is most often caused by incorrect optical distribution rather than insufficient power.

How is light distribution verified in professional projects?

Professional verification typically includes:

Lighting simulations using manufacturer IES files

Review of LM-79 photometric test reports

On-site illuminance measurements after installation

This process ensures that the selected distribution performs as expected under real conditions and meets applicable standards.

Which standards are commonly used to evaluate street lighting distribution?

Street and road lighting performance is commonly evaluated using standards and guidance from the Illuminating Engineering Society (IES), such as IES RP-8, and regional standards such as EN 13201. These frameworks emphasize distribution, uniformity, and glare control rather than wattage or raw lumen values.

Call to Action (CTA)

Plan Light Distribution Before Choosing Power

In professional street and road lighting projects, choosing wattage or lumen output should never be the first step. Performance depends on selecting the right light distribution, then verifying it using objective data and simulations.

If you are planning a street lighting, road lighting, or public outdoor lighting project, focus first on:

Road type and width

Mounting height and pole spacing

Required uniformity and glare limits

Appropriate IES distribution type

Well-designed light distribution reduces energy use, improves visual comfort, and avoids costly redesigns.

If you need help reviewing light distribution options, photometric data, or simulation assumptions for your project, work with a supplier or engineering team that can provide IES files, LM-79 reports, and verifiable performance data, not just catalog lumen numbers.