Introduction: Why “lifetime led” Is More Than a Number

When people see “50,000 hours” on an outside led light, it sounds safe and reliable.

But experts in city lighting, factories, or OEM projects know that lifetime led is not fixed — it comes from good design.

People often ask, “do led lights burn out?”In reality,Every hour of use depends on small things: how heat moves from the chip to the housing, how stable the driver current is, how the coating protects against salt air, and how the software keeps the LED cool.

At LinkLights, we build truly long lasting lamps by treating lifetime not as a sales claim, but as an engineering promise — proven by strong materials, thermal design, and long testing.

This article shows how LED life is set by standards like LM-80, TM-21, and EN 60598, and why two lights with the same “50,000 h” label can last very differently in real life.

The Myth of “50,000 Hours” — What LED Lifespan Really Means

Where the number comes from

Most led lightbulb makers test lifetime by checking how light fades over time.

The LM-80 standard from the Illuminating Engineering Society measures how an LED keeps its brightness during 6,000–10,000 hours of lab testing.

Then the TM-21 method uses that data to predict when brightness will drop to a set level — usually L70, meaning 70% of the first brightness.

Many people ask, “How long is 50,000 hours?”In simple terms, “50,000 hours” means that under normal use, the LED will still give about 70% of its original light after 50,000 hours.That equals about 13 years if you use the light 10 hours a day.

But this number does not include the driver, lens, housing, or environment — those parts might fail much sooner.

System vs Component lifetime

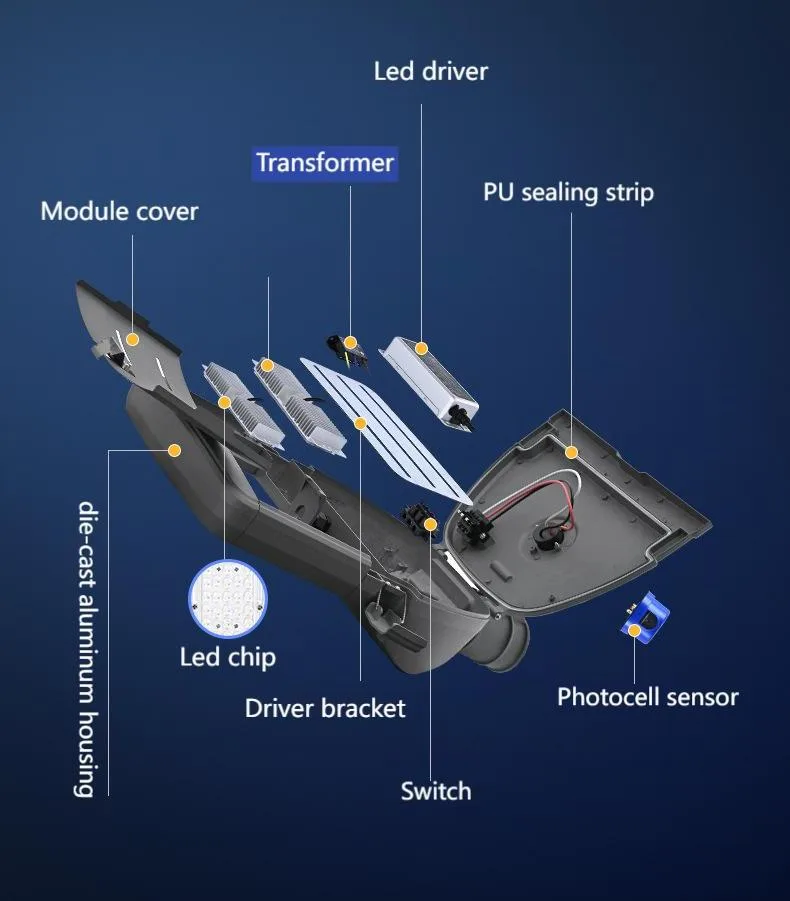

An LED light is not made of one part.

Its life depends on the weakest link in the system:

LED Chip → PCB → Thermal Interface → Heat Sink → Driver → Optics → Housing → Environment

If the driver’s capacitor lasts only 30,000 hours, or if dust makes the LED too hot, the whole light will fail much sooner.

So, for real projects, system reliability — not just part life — is the true measure of quality.

Beyond lumen depreciation

Led outdoor lights rarely burn out completely.Instead, they get dimmer over time (called lumen loss), their color may shift (CCT drift), or some led light modules age unevenly.

In real projects, many designers use L80B10 or L90B10 as the target life.

This means the light keeps 80–90% of its brightness, and no more than 10% of units fail.

These rules help engineers keep even lighting for roads, sports fields, or workplaces.

They also follow standards like EN 13201, which sets the minimum brightness and uniformity for city streets.

Engineering the Real Lifetime — Design + Validation

Design Foundation: LED, Driver, Thermal, Environment, Control System

In real use, long life light bulb depends on many parts

LED Chip + Driver + Heat Control + Environment + Control System = Real Lifetime

All parts work together. If one part fails, the others cannot make up for it.

LED Chip:Modern LED chips can achieve over 200 lm/W, forming the luminous core of today’s high-efficiency LED Lamps. However, if they run with too much current, they overheat and lose brightness faster. At LinkLights, we drive Osram and Philips LEDs at no more than 70 % of their rated current—keeping both the chip and the lamp cooler, protecting the phosphor, and extending lifetime to L90 > 60,000 hours.

Driver:The driveris often the weakest part.Its life depends on the capacitor quality, temperature, and surge protection.We use MOSOor Mean Well drivers rated for 100,000 hours @ 60 °C, with 10 kV surge guards and > 92 % efficiency.This keeps the power steady for the whole LED system.

Thermal Management:Every 10 °Cincrease in LED temperature can cut its life by about 50 %.Our ADC12 die-cast aluminum housingjoins the LED board and led light bulb heat sink into one solid structure.With CFD simulation and wind-tunnel tests, we keep the case under 60 °C even when the air is 35 °C.Lower heat resistance (Rθ < 0.5 °C/W) means slower aging, better brightness, and less color change.

Environment:Heat, humidity, salt, dust, and vibration can shortenlifespan of an led.LinkLightsuses triple coating, IP66–68 sealing, and 1,000 h salt-spray tests (IEC 60068-2-52).This makes our lights work reliably in coastal, industrial, or desert areas.

Control System:Smart controls such as 0–10 V, DALI-2, Zhaga, LoRa, or NB-IoTsave energy and extend led lifespan.They dim lights during quiet hours to reduce heat stress.Smart data also finds lights close to failure, allowing planned maintenance instead of sudden repairs.Real led light bulb lifespan comes from the whole system working together, not one single part.LinkLights designs balance the LED, driver, cooling, environment, and control to deliver many years of reliable service.

Validation in Lab and Field: Accelerated Testing, CFD, Field Feedback, Weibull Reliability

Accelerated Life Testing:Waiting 100,000 hours is impossible, so engineers use accelerated tests.Lights are run at higher heat and current to reveal weak points early.

Models like Arrhenius and Weibull predict real-life results.At LinkLights, we test with:

1,000 h thermal shock (−40 °C to +80 °C)

85 °C / 85 % RH humidity aging

3,000 h continuous burn-in

These confirm both LED and driver durability.

Thermal Imaging & CFD Simulation:We use infrared cameras and CFD airflow models to locate hot spots.This keeps temperature within safe limits, even under wind or pole tilt.

Field Validation:We collect data from real projects.One 100,000-hour streetlight in Southeast Asia showed less than 5 % lumen loss after 20,000 hours, thanks to salt-resistant coatings and smart dimming.

Statistical Reliability:We analyze failure probability using Weibull and B10/B50 metrics.Instead of one number, we show a lifespan range, helping planners plan maintenance.

Key Point:

Reliability is proven by testing and data, not by claims.

Standards, Compliance & Specification Writing

Led lifetime isn’t just a number — it’s proven through standards and testing.

This section explains how LM-80, TM-21, and EN 60598 define real-world led light lifespan and how to apply them in lighting projects.

LM-80 / TM-21 / EN 60598 Explained

If we want to talk seriously about led light lifetime, we must use the right standards — not marketing guesses.

Three key documents define how led light longevity is measured and verified: LM-80, TM-21, and EN 60598.

LM-80 — Measuring How Light Fades

LM-80-15 from the Illuminating Engineering Society (IES) explains how to test LED packages for brightness and color loss over time.

LED chips are operated for 6,000–10,000 hours in controlled lab conditions. The data shows how light output and color hold up under heat and electrical stress.

TM-21 — Predicting Future Performance

TM-21-19 takes LM-80 data and uses a mathematical model to predict how light will fade in the future.

Results are expressed as L70, L80, or L90, meaning the LED keeps 70%, 80%, or 90% of its original light output after a given number of hours.

Example:“L90 = 60,000 h @ 25°C” means the LED maintains 90% of its brightness after 60,000 hours at 25°C.

LM-84 — Testing the Whole Luminaire

While LM-80 focuses on the chip, LM-84-14 measures the performance of the entire light — including the driver, lens, and thermal design.

This gives a more accurate picture of how a luminaire performs in real-world use.

TM-28 & TM-31 — Color and Flicker Stability

These standards check color shift (Δu′v′) and flicker stability, ensuring that architectural or roadway lighting maintains uniformity — a key requirement in IES RP-8 and EN 13201.

EN 60598 — Safety and Protection

EN 60598 ensures that every luminaire is safe, sealed, and structurally sound.

Tests include dielectric strength, grounding, thermal endurance, and IP/IK protection.

A product cannot claim a “100,000-hour life” if it fails these environmental or mechanical tests.

🔹 What “Lxx Bxx” Means

| Code | What It Means | Example |

| L70 B50 | 70 % of light kept; 50 % of units below this | Normal lifespan |

| L80 B10 | 80 % of light kept; 10 % below | High-quality design |

| L90 B10 | 90 % of light kept; 10 % below | Premium-grade performance |

These values help engineers compare LED quality fairly.

Always trust LM-80 / TM-21 / LM-84 reports — not marketing claims.

The Lxx Bxx values, test temperature, and environment define the real led lamp lifespan.

How to Apply These Standards in Project Specs

Understanding these standards is only the first step.

To build long-lasting LED lighting systems, engineers must turn the test data into practical specifications.

Here’s how to apply standard-based targets when designing or evaluating LED lighting for streets, factories, or public spaces:

| Specification Item | Recommended Level | Why It Matters |

| Lumen Life (L80 / L90) | ≥ 60 000 h | Ensures consistent brightness over years |

| Driver Lifetime | ≥ 60 000 h @ Tc ≤ 70 °C | Prevents capacitor aging and early failure |

| Thermal Resistance (Rθ ja) | ≤ 0.5 °C/W | Keeps LED junction below 85 °C |

| Ingress Protection (IP) | IP66 – IP68 | Blocks dust and water outdoors |

| Impact Resistance (IK) | IK08 or higher | Prevents mechanical damage |

| Surge Protection (SPD) | ≥ 10 kV | Protects against grid or lightning surges |

| Warranty Period | ≥ 10 years | Reflects design confidence and reliability |

Each of these lines maps to a specific standard:

LM-80 / TM-21 → defines lumen-maintenance ratings (L70–L90)

EN 60598 → defines IP / IK protection and structural safety

IEC 61000-4-5 → defines surge immunity

Together, these ensure your lighting system achieves verified 10-year reliability, not just a “lab-tested” lifespan.

Example Use Case:

A city project specifying “L90B10 ≥ 60 000 h, IP66, 10 kV SPD, 10-year warranty” ensures that every component — chip, driver, and housing — works together for real longevity.

Recommended Wording for Tenders

Clear tender wording helps both buyers and suppliers avoid confusion.

Instead of vague promises, use specific, test-based language that can be verified through standards.

Suggested Tender Language

The luminaire shall achieve L90 B10 ≥ 60 000 hours at 25 °C ambient temperature,with driver lifetime ≥ 60 000 hours and a minimum 10-year system warranty.All testing shall comply with LM-80, TM-21, and EN 60598 standards.”This simple clause turns a “lifetime claim” into a measurable engineering commitment.

It ensures that all bidders design for proven reliability rather than the lowest cost.

ROI and Case Validation — Why Reliability Pays

The ROI Logic

For cities or factories, lifetime means lower cost:

Fewer lift-truck visits

Less downtime

Smaller spare-part inventory

Safer, brighter streets

Modern LEDs use 75 % less power and last 25× longer than old lamps.

Since energy + maintenance = 80 % of total cost, longer life cuts spending fast.

The LinkLights ROI Model

At LinkLights, we calculate ROI using a simple but proven formula:

ROI = (Maintenance + Energy Savings – Extra Cost) ÷ Extra Cost

In typical streetlight upgrades, payback happens within 3–5 years.

| Metric | HPS | LinkLights LED | Improvement |

| Rated Life (h) | 15 000 | 100 000 | 6.7× longer |

| Maintenance Cycle | 2 years | 10 years | 5× less service |

| Energy Use (kWh/yr) | 460 | 180 | −61 % |

| Payback | – | ≈ 3 years | ROI positive after Year 3 |

Lifecycle models also include energy cost, labor, failure risk, and recycling.

Doubling lifetime from 50 000 → 100 000 hours reduces total ownership cost by ≈ 28 %, even if the purchase price is 25 % higher.

Many governments now reward long-life LED systems through green procurement credits and carbon-reduction programs.

Products with LM-80 / TM-21 data often qualify for extended warranties and ESG points.

Case Study: 100 000 h vs 50 000 h Systems

To prove the numbers, LinkLights compared its 100 000 h model with a standard 50 000 h market fixture in a coastal city.

| Metric | LinkLights | Market Model | Difference |

| Lumen Maintenance @ 7 000 h | L94 | L86 | +9 % brightness retention |

| Case Temperature | 57 °C | 72 °C | −15 °C cooler |

| Driver Failure | 0 % | 3.8 % | – 3.8 pp |

| Salt-Spray Resistance | No change | Visible corrosion | Superior coating |

Result:

Better thermal design and surge-protected drivers help LinkLights luminaires last almost twice as long, even in harsh coastal environments.

Extreme Environments and Sustainability

Durability and sustainability share the same goal — lights that survive longer and waste less.”

Extreme Environments

High Heat: Add larger heat sinks and limit current at > 40 °C.

High Humidity: Use epoxy + polyester coatings, salt-spray tested 1,000 h.

Cold or Tunnel: Use film capacitors and IK08+ impact ratings.

Smart Dimming: Each 3 °C cooler adds ~5,000 h to lifespan.

Durability = thermal + corrosion + electrical + smart control protection.

Sustainability and Circular Design

Longevity = Green Impact

Fewer replacements = less waste and CO₂.

DOE data: longer LED life cuts total footprint by 30–40 %.

Design for Recycling

Modules use standard screws and recyclable aluminum housings.

Lenses marked for PMMA / PC recycling.

Smart End-of-Life

Firmware logs usage and alerts teams before failure, turning maintenance into planning.

Key Point:

Sustainability means lights that last longer and return safely to the material loop.

FAQ Highlights

Do LED lights really last 100 000 hours?

Only when the entire system — chip, driver, heat sink and environment — is engineered for that duration and tested under LM-80/TM-21 protocols. Otherwise, expect 50 000–70 000 hours.

What fails first in an LED fixture?

Typically the driver’s electrolytic capacitor or the solder joint on the LED board. Thermal cycling accelerates both.

Do LED lights get dimmer over time?

Yes. They gradually lose lumen output as phosphor and optical materials age. The rate depends on temperature and drive current.

How can I verify lifespan claims in datasheets?

Look for LM-80/TM-21 data, Lxx Byy notation, and ambient temperature reference. Ask for driver life and test temperature as well. For details, see How to Read LED Lifetime Data Sheets.

How does smart dimming affect lifespan?

Reducing current through dimming lowers junction temperature, often extending life by 10–20 %. Poorly matched drivers may offset this benefit. Learn more in How Smart Controls Extend LED Lifespan.

What’s the difference between L70 and L90?

L70 means the light has 70 % of its original brightness left; L90 is 90 %. Higher L-values indicate better lumen maintenance and usually more robust thermal design.

Conclusion — From Hours to Trust

Reliability is designed, not declared.

Through thermal, driver, and system engineering, LinkLights turns lifetime into a promise of trust.At LinkLights, lifetime is not a claim — it’s a design commitment.

By choosing verified standards and smart design, you invest in long-term performance, safety, and sustainability.