Introduction: Why led flood lights Fail

LED flood lights are very popular for outdoor use. They give led light longevity, save energy lighting, and steady brightness. But problems can still happen. Many people see outdoor flickering light bulbs, some lighting chips going dark, or even a full blackout. These failures hurt the safety of led lights and can make a trusted led security flood light unsafe. For homeowners, this means weaker protection at night. For businesses and cities, broken LED security flood lights bring more repairs and raise the cost of led lights because of downtime and replacements.

This guide will explain the common reasons why LED flood lights fail, how you can check the problem, and what to do to make your lights last longer.

Power Supply and Driver Issues

The Role of the LED Driver

Every led floodlight needs a driver to make the power safe for the LED chips. LEDs use low-voltage direct current (DC), but most power grids give high-voltage alternating current (AC). The driver changes AC to DC and keeps the current steady.

When the driver goes bad, outdoor flood light bulb may stop working in part or fully. Signs of trouble include:

Complete blackout—when the driver stops working, all the led light bulbs for floodlights go out.

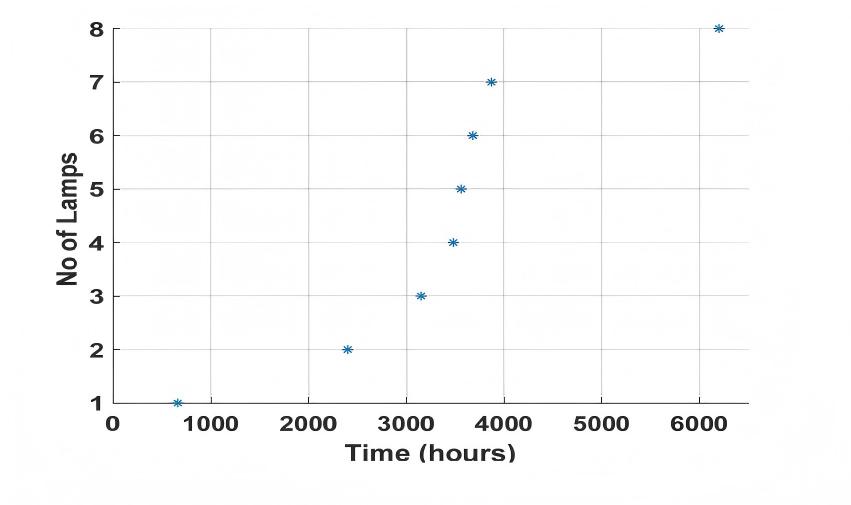

Real-world testing confirms this risk. According to a study published in Energies (MDPI) ,poor-quality drivers or unstable power supply conditions can cause flood lights to experience complete blackout far earlier than their rated lifespan. For example:

some street lamps went completely dark after only 660 hours of operation, while more failed between 2400 and 6200 hours. This is far below the commonly claimed lifespan of 25,000 C50,000 hours, showing that driver for led light failures directly lead to the premature death of LED flood lights.

Flickering or dimming

The constant current driver is the key part of outdoor flood lights, but it is also the part that fails most often in public led lights for projects. A driver is usually set to work in a fixed voltage range (like 30 C60V or 100 C240V). When the led module light source runs within this range, the current stays steady, and the light is bright and even. But if the constant current driver gets old or breaks, the output becomes unstable, causing flicker or early failure.

Visible dimming over years of operation, often linked to driver instability or failure.

Issue of improper thermal design

If the led floodlight outdoor cannot get rid of heat well, its life will get shorter. In worse cases, the light may stop working. For led drivers, poor cooling can make them turn on and off often, which also reduces their life. This is why makers of exterior led floodlights must watch the working heat of both the chips and the drivers.

SPD performance issues

Led flood lights are used outdoors and can be hit by strong surges from lightning. The driver has a built-in surge protector that reacts at once to sudden voltage or current spikes. It lowers the extra power to a safe level and sends it to the ground. This keeps the driver and LED chips safe and helps the light work well and last long, even in bad weather.

Compatibility of the driver

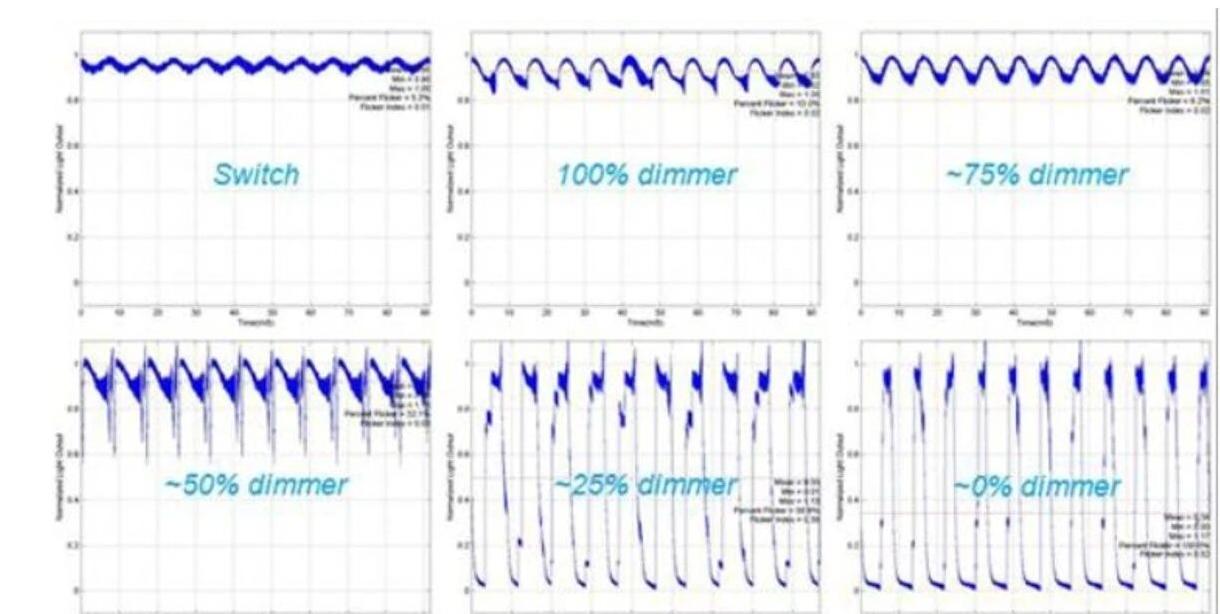

The design of the led flood light driver and how well it matches the dimmer greatly affect led flood light flickering. Different drivers perform very differently.In a dimmable flood light When a dimmer is used, the flicker gets worse as brightness goes down from 100% to 50% and then to 25%, as shown in the figure. This shows that poor driver Cdimmer matching can cause serious flicker problems.

Poor Quality Components

Poor-quality parts are a main reason led flood lights outdoor fixtures fail. Cheap drivers often use bad capacitors, rectifiers, or diodes, and lack surge or heat protection. This makes them easy to break from surges, heat, or unstable output, causing flicker in led lighting, dim light, or early failure. Studies show that weak cooling and low-grade parts speed up driver aging and cut the reliability of outdoor lights.

Trouble shooting Driver Failures

In flood lights, a bad driver can cause low output voltage, making the flood light flickering or go out. A common problem is capacitor damage in the driver, such as bulging, leaking, or burn marks, with the value no longer matching its rated range. In these cases, the driver or capacitor should be replaced at once. Using replacement LED drivers that fit the flood light s module, and the capacitor should have the same rating or a higher voltage rating to keep the light stable and extend its life.

Preventing Driver-Related Failures

Always pick flood lights with good brand drivers (like Mean Well, MOSO, or Philips).

Make sure the driver has surge protection to handle voltage spikes.

Use lights with proper heat sinks and housing to stop overheating.

Match the driver s output voltage and current with the LED chips.

Wiring and Connection Faults

Another major reason why flood lights outdoor stop working lies in wiring problems. Even the best LED chips and advance led drivers cannot function if electricity cannot flow smoothly from the source to the light.

Common Wiring Issues

Loose Connections : In flood lights outdoor bulbs, long-term vibration, poor installation, or ground settlement can loosen cable joints. This makes the power unstable and often causes flood light flickering problem, random shutoffs, or even short led circuits.

Faulty Solder Joints : In flood lights bulbs outdoor with multi-chip series Cparallel modules, cold solder joints or PCB cracks can create weak electrical connections. This may lead to some flood light not working, uneven light, or faster damage to other chips.

Damaged Cables :flood lightbulbs that face sun, rain, wind, sand, salt spray, and lightning over time often suffers from cable insulation aging, bending, or breaking. Loose or damaged joints can also create leakage risks

Polarity Errors :In dc led flood lights, reversing the positive and negative wires can damage the driver or the chips.

Wiring Problem Diagnosis and Solutions

| Diagnosis | Solutions | Prevention |

| Use a continuity tester to check if current flows through the wires. | Tighten all terminal connections to ensure firm contact. | Follow the manufacturer’s wiring diagrams carefully. |

| Inspect solder joints under magnification for cracks or discoloration. | Replace damaged cables with UV-resistant, weatherproof wires. | Use junction boxes and conduits for outdoor installations. |

| Gently wiggle connectors to see if flickering occurs. | Use waterproof connectors for outdoor applications. Apply protective coatings or sealants to solder joints exposed to humidity. |

Conduct regular inspections, especially in harsh environ |

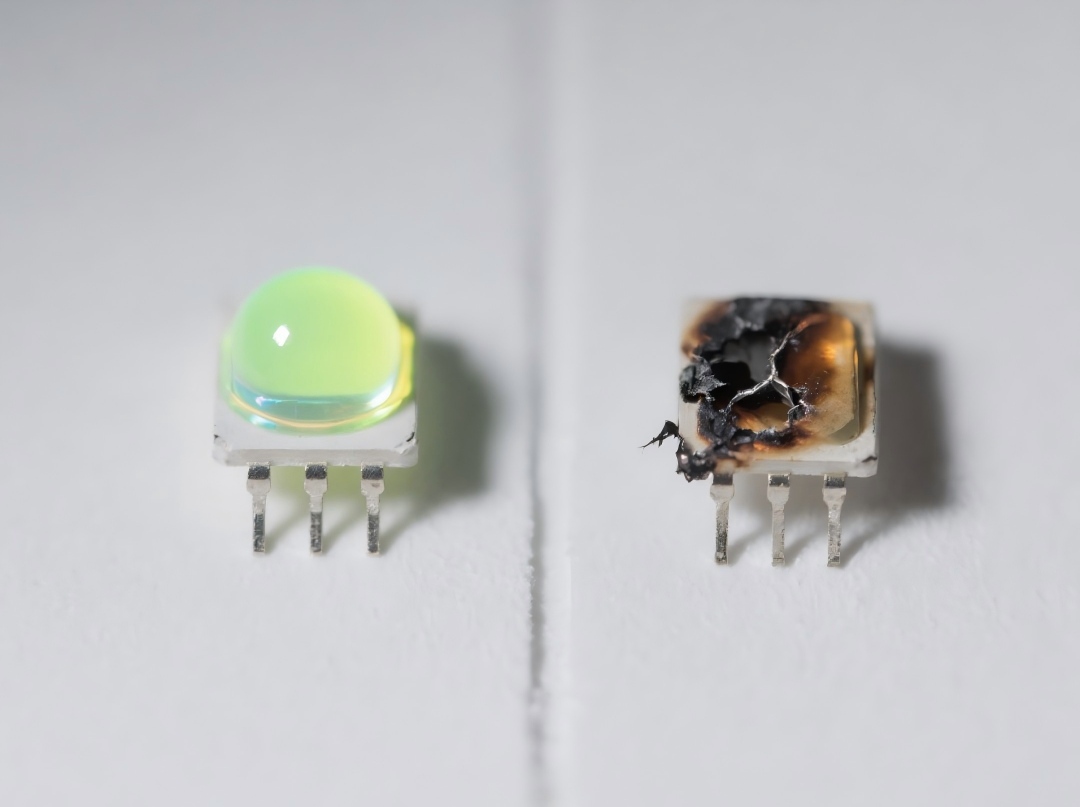

LED Chip or Module Failure

Even though LED chips are designed to last tens of thousands of hours, they are not immune to damage. In many cases, users notice that only part of the new flood light not working some chips light up, while others remain dark. This symptom usually indicates chip-level or module-level failure.

Common Causes of Chip Failure

Over Current Stress

In led outdoor flood lights bulbs, if the current is higher than the rated value, the chip junction gets too hot. This causes material damage and current crowding. Over time, the light output drops, the chip may burn out, and the lamp life becomes much shorter.

Electrostatic Discharge (ESD)

ESD can break LED chips right away, causing hard failures where the outdoor flood light not working. Even if damage is not seen at once, soft failures may cause lessen the brightness of flood light, color changes, and shorter life. In outdoor LED flood lights, no ESD protection during production, shipping, or installation can cause early failure and fast flood light lumen loss. This raises repair costs and lowers system reliability.

Poor Quality LEDs

In LED flood lights, the chip and electrode are joined with bonding wires. If poor chips with copper or silver alloy wires are used, they may work at first. But after thousands of hours in heat and humidity, bond wires can fail or detach. This causes some LEDs to go dark, uneven lighting, or even total failure, cutting the service life short.

Phosphor Degradation

The phosphor layer can get hotter than the LED chip. This local heat lowers light conversion efficiency. High heat speeds up phosphor aging, which shortens the life of the LED light.

LED Chip Problem Diagnosis and Solutions

| Symptoms | Diagnosis | Prevention |

| Certain LEDs in the array stop glowing | Inspect individual LED modules with a tester | Choose flood lights with Osram, Cree, or Philips chips, which are tested for durability |

| Uneven brightness or noticeable dark spots | Use a thermal camera to check for hot spots that indicate damaged chips | Handle LEDs with ESD protection during installation |

| Yellowing or black spots on the chip surface | Compare brightness levels across the array | Ensure proper heat dissipation so chips don’t overheat Avoid overdriving LEDs beyond their recommended current |

Heat Management and Thermal Stress

Heat is the main enemy of LED life. Unlike old bulbs that release heat, LEDs keep heat in their junctions. If heat is not removed, it builds up and speeds up failure.

Why Heat Matters in LED Flood Lights

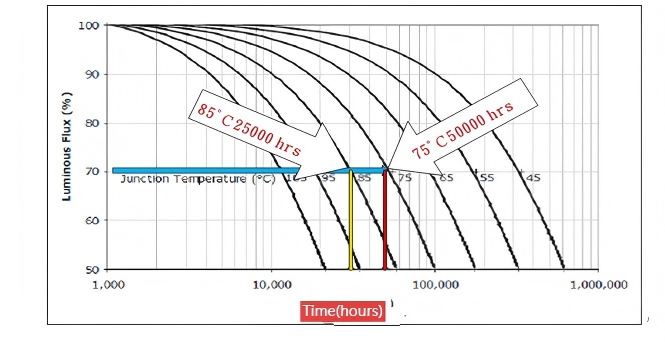

High Junction Temperature Reduces Light Output

Led flood light fixtures often use many chips in one module. If the junction gets too hot, efficiency drops, color shifts, and light becomes uneven. A CREE report shows that lowering the junction temperature by 10 can double the LED s life and raise light output by 3% -8%. Keeping it at 85 is key for long life and good performance.

Excess Heat Damages Solder and PCB

If the led flood light heat sink is not good enough, heat builds on solder joints and the PCB. This can melt solder, crack joints, or warp the PCB. The result is some LEDs going out, flickering, or in serious cases, total lamp failure.

Drivers Age Faster in High Heat

Light drivers sit inside the flood lights aluminum die casting housing and get exposed to heat. Electrolytic capacitors are most sensitive. Their life is cut in half for every 10 rise. Without good cooling, drivers may fail in only a few thousand hours, making them the top failure point in flood lights.

Common Heat Issues (in LED Flood Lights)

Poor Heat Sink Design

Some cheap floodlight lights use thin aluminum light cover for flood light without fins, giving too little surface area to release heat. Even with thermal paste or heat pipes, heat may spread unevenly, creating hot spots and lowering cooling. On flood light poles 8 -12 meters high, bad heat sink design can also be a safety risk during typhoons or earthquakes.

Dust Accumulation

On roads, in factories, or in stadiums, dust and sand can block air holes, reduce airflow, and raise inside temperature. This is worse for lights close to the ground or in windy, sandy areas.

Improper Installation

If LED flood lights are placed in sealed or airless spaces, heat builds up around the light. This keeps chips and drivers too hot, causing early lumen loss and shorter driver life.

Solutions

Use flood light aluminum housing and fin-type heat sinks.

Ensure led light bulbs for floodlights are installed in areas with good airflow.

Clean dust and debris regularly.

Opt for designs with double-layer convection channels for faster cooling.

Long-Term Benefits

With effective heat management, LEDs maintain their brightness longer, drivers last years beyond warranty periods, and users save money on replacements.

Environmental and External Factors

Even the best-engineered LED flood lights face challenges when installed outdoors. Weather, humidity, and physical damage can all shorten their lifespan.

Key Environmental Threats

Moisture and Water Ingress

Outdoor flood lights must face snow, sun, and rain for many years. They cost a lot and are hard to fix, so stability is key. LEDs are sensitive parts that get damaged by moisture. If sealing is poor, water can harm the LED, PCB, and other parts. That is why IP65/IP66/IP68 waterproof flood light design is needed to stop rain or condensation from causing short circuits.

Corrosion

In coastal or industrial areas, salty air or chemicals can eat away metal contacts and harm PCB layers. In humid places, moisture can cause mold to grow, which corrodes the power supply case and inside parts. These problems together make the product s life much shorter.

Extreme Weather

Outdoor temperatures change a lot each day. In summer, the light s surface can reach 50 C60 in the day and drop to 10 C20 at night. In winter, it can fall below zero. Such changes speed up material aging and warping in high heat. When it is below zero, plastic parts turn brittle and may crack under snow and ice.

Physical Damage

Impact from balls, debris, or vandalism may crack housings or break connections.

Preventive Measures

Always choose led flood light fixtures outdoor with high ip waterproof ratings for outdoor applications.

Apply anti-corrosion coatings for installations near the sea.

Use polycarbonate or tempered glass lenses for impact resistance.

Ensure gaskets and seals are intact during installation.

Diagnosing LED Flood Light Problems

Knowing the root cause of failure helps users decide whether to repair or replace their flood lights.

Quick Troubleshooting Checklist for LED Flood Lights

| Step | What to Check | How to Diagnose | Possible Action |

| Visual Inspection | Any visible damage | Look for burn marks, discoloration, cracks, or water traces | Minor issues can be repaired; severe damage may require replacement |

| Power Supply | Input voltage | Use a multimeter to test input (AC 85–265V or DC 12V, etc.) | If no input, check the circuit or power switch |

| Driver | Driver condition | If input is present but the light is off → driver may be faulty | Replace with a matching replacement LED driver |

| LED Chips | LED chip health | Test chips individually; check for black spots, yellowing, or uneven brightness | Replace module if minor; multiple failures may require full fixture replacement |

| Wiring & Connections | Wiring stability | Inspect solder joints and connectors; gently wiggle to see if flickering occurs | Tighten terminals, replace aged or damaged cables |

| Environmental Damage | Signs of corrosion or dust | Check for rust, moisture, or dust buildup | Clean dust, check gaskets, apply anti-corrosion coating if needed |

| When to Call a Pro | Beyond user capability | Driver rewiring, chip soldering, or module replacement required | Call a professional or consider full replacement |

FAQ: Common User Questions

Q1: Can LED flood lights be repaired?

Yes, but it depends on the fault. Drivers and wiring are repairable; burned-out chips often require full replacement.

Q2: How long should an LED flood light last?

High-quality models last 50,000 hours or more (10 C15 years of typical use).

Q3: Why do only some chips stop working?

Usually due to uneven current distribution, overheating, or localized chip defects.

Q4: Can I replace just one LED chip?

Technically yes, but it requires soldering and expertise. For most users, replacing the module or fixture is easier.

Q5: How to prevent early failure?

Buy from reputable brands, ensure proper installation, protect from surges, and perform regular cleaning.

Conclusion: Maximizing LED Flood Light Lifespan

LED flood lights are made to last, but no product can fully avoid wear, bad weather, or mistakes in setup. By knowing the main causes of failure power supply problems, chip damage, wiring faults, heat, and outdoor conditions users can act early to find, stop, and fix issues.

Key points for users:

Choose quality lights with tested chips and drivers.

Install them the right way and protect from surges, water, and heat.

Check and clean them often to spot problems early.

By doing this, you will get better performance, lower repair costs, and enjoy steady lighting for many years.