Large industrial and commercial spaces depend on one essential asset: reliable, uniform, and energy-efficient led high-bay lighting. Warehouses, factories, logistics centers, retail stores, hangars, gymnasiums, and sports halls all require powerful illumination that can reach the ground from mounting heights of 20–60 ft while maintaining safety, productivity, and energy control.

This guide explains everything you need to know about led high bay lighting—from engineering fundamentals to system design, photometric requirements, and long-term ROI.

It is written for B2B buyers, electrical contractors, distributors, project managers, and facility engineers who need a trustworthy, specification-grade reference.

What high bay lighting led Really Is — And Why It Matters

High bay lighting refers to luminaires installed at elevated mounting heights where ordinary fixtures cannot deliver enough illumination. Typical ranges include 20–40 ft for warehouses and production floors, and 40–60 ft for logistics hubs, aircraft hangars, gymnasiums, and sports arenas. Because the distance between the light and the working surface is large, these environments demand high-performance LED highbay lighting engineered to maintain visibility, safety, and efficiency.

To achieve compliant lighting levels, high-bay applications require:

High lumen output to deliver sufficient lux at 20–60 ft mounting heights

Precision optical control (60°, 90°, 120°, aisle beams) to reduce wasted light and improve uniformity

Wide but uniform coverage for open production areas and tall racking aisles

Minimal glare to support worker comfort and forklift safety

Low maintenance made possible by LED L70/L90 lifetimes of 50,000–100,000 hours

Long operating life backed by LM-80 and TM-21 validation

Optional smart controls such as motion sensors, daylight harvesting, and DALI/0–10V dimming to reduce energy consumption

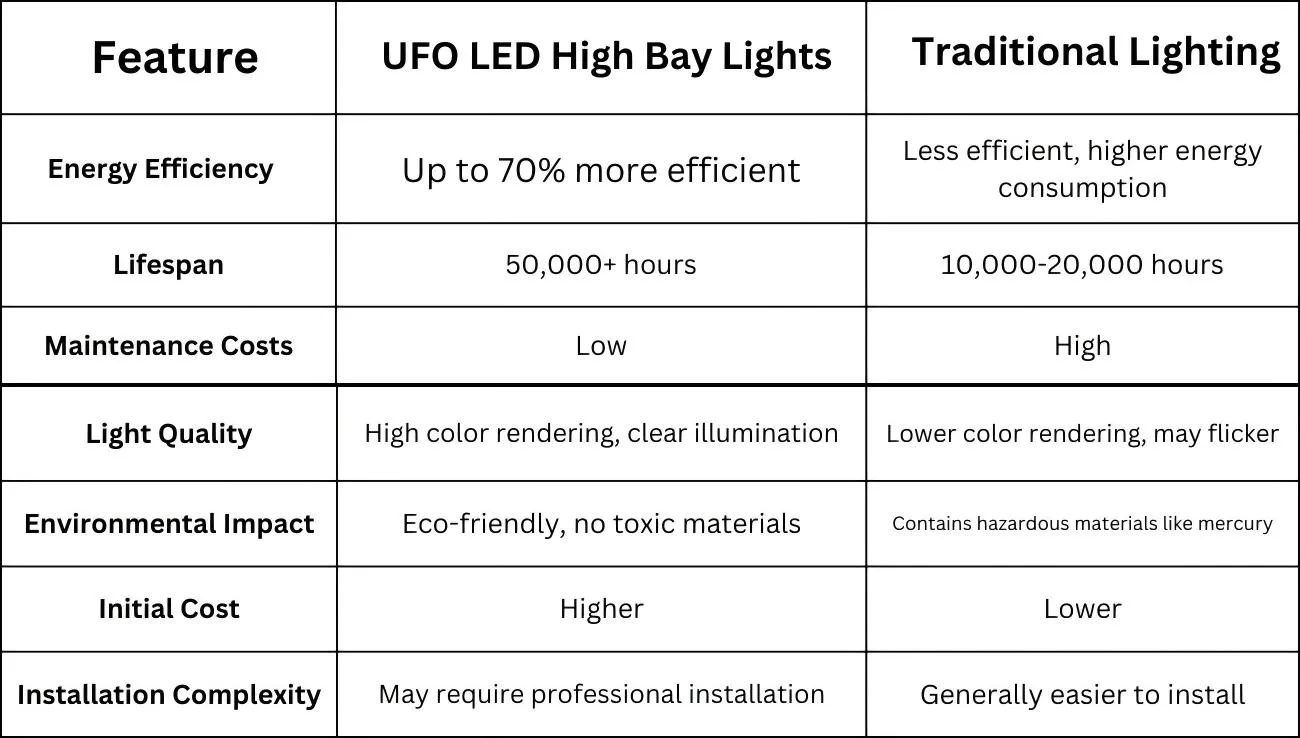

Because of these performance requirements, LED high bay lighting fixtures—UFO, linear, and high-mast styles—have become the global standard, replacing outdated metal halide, HPS, and fluorescent systems. Modern LED high bays offer 2–4× higher efficiency, 5–10× longer lifetime, and far better optical distribution, making them the preferred choice for large industrial lighting projects, warehouse lighting upgrades, and energy-saving retrofits.

Why LED High Bay Lighting Replaced HID and Fluorescent Systems

Energy Efficiency and Power Savings

Led high bay lighting fixtures use far less energy than old metal halide high bay lights or HPS fixtures. A 150W LED can replace a 400W metal halide, saving 60–70% of electricity while giving the same or even brighter light. Modern industrial LEDs reach 130–170 lm/W, much higher than the 70–90 lm/W of high bay metal halide lights. Because LEDs turn more power into light instead of heat, facilities like warehouses and logistics centers can lower electricity bills, reduce heat buildup, and improve overall energy efficiency.

Instant-On and Flicker-Free Output

Metal halide high bay light fixtures take 5–15 minutes to warm up and even longer to restart after a power outage. LED high bays turn on instantly with full brightness, making them ideal for motion sensors, dimming systems, emergency lighting, and busy warehouse areas where lighting changes quickly. LEDs also offer flicker-free performance, meeting IEEE 1789 guidelines. This reduces eye strain, prevents camera flicker in security systems, and improves safety around forklifts, robots, and fast-moving equipment.

Longer Lifespan and Lower Maintenance

Industrial led high bay lights last 50,000–100,000 hours, much longer than the 8,000–15,000 hours of high bay metal halide lights. Since industrial high bay lighting fixtures are mounted 20–60 ft high, replacing old lamps requires lift trucks, trained workers, and scheduled downtime. By switching to LED, facilities reduce relamping, fewer lift operations, and lower maintenance costs. This long lifespan creates fast ROI and is one of the main reasons warehouses, factories, and 24/7 operations are moving to LED high bays.

Better Visibility and Worker Safety

Led high bay light fixtures provide clearer and more comfortable lighting than older HID fixtures. They offer higher CRI, so colors and labels are easier to read. They also deliver more even light, reducing dark areas and shadows. With the right optics—such as prismatic lenses or asymmetric beams—LEDs cut glare and reduce eye fatigue. This leads to safer forklift movement, better picking accuracy, fewer accidents, and an overall safer working environment, meeting OSHA and EN 12464-1 lighting standards.

Types of high bay led lighting fixtures (UFO vs Linear)

UFO high bay lighting

Best ufo led high bay lights are round, compact, and designed for high-efficiency lighting in industrial and commercial spaces. Their durable die-cast aluminum housing provides strong heat dissipation, while 60°, 90°, and 120° beam options make them ideal for warehouses, factories, workshops, and logistics centers with medium to high mounting heights. high bay ufo led install quickly using hook or pendant mounts, making them a preferred choice for fast retrofit projects. Their high lumen output, wide coverage, and stable performance make them one of the most popular industrial lighting fixtures.

Linear LED High Bay Lights

Linear industrial warehouse lighting fixtures use a long rectangular design that delivers wide, uniform illumination—perfect for aisle warehouses, supermarkets, sports halls, and production lines. Their elongated optical layout provides better coverage between tall racks and reduces dark spots in narrow corridors. Linear high bays also simplify photometric planning because spacing is easier to calculate over long distances. For facilities with shelving, long aisles, or task-specific zones, linear LED high bays offer superior visual comfort, better uniformity ratios, and improved workflow visibility.

Why Both Types Matter for Buyers

Both UFO and linear LED high bay lights serve different lighting needs within the same facility. UFO high bays are ideal for open spaces that need high lumen output and easy installation, while linear high bays excel in aisle lighting and long operational zones. Offering both ensures buyers can choose the correct fixture based on mounting height, layout, optical needs, and desired uniformity. This improves overall efficiency, reduces the number of fixtures required, and delivers better long-term performance for industrial projects.

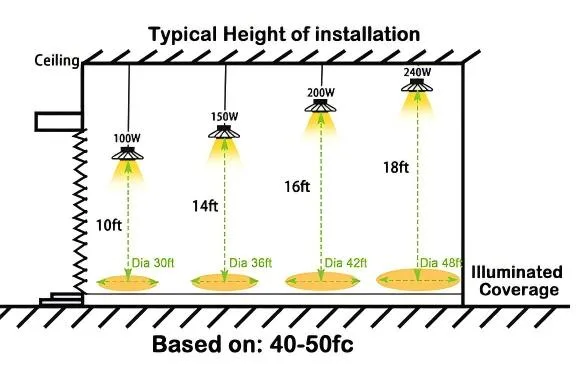

How to Choose the Right Lumen Output

Because wattage no longer indicates brightness, B2B buyers must evaluate lumens.

Typical ranges:

| Ceiling Height | Recommended Lumens per Fixture |

| 10–20 ft | 10,000–20,000 lm |

| 20–30 ft | 20,000–30,000 lm |

| 30–40 ft | 30,000–45,000 lm |

| 40–60 ft | 45,000 lm or higher |

→ Visit our high bay LED light category to compare lumen options

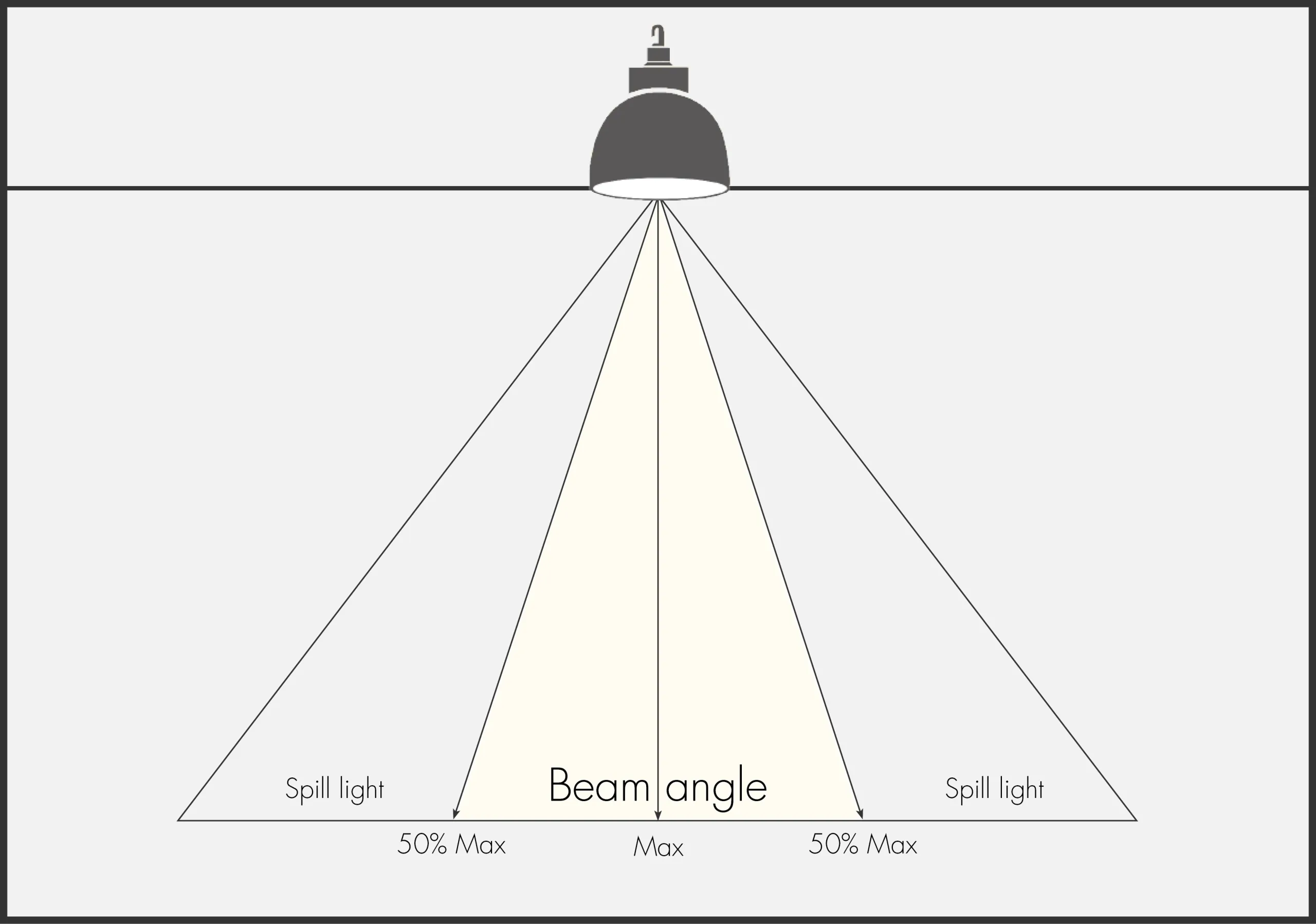

Optics and Beam Angles — The Most Overlooked Specification

Common Beam Angles for high bay industrial lighting

High-bay spaces have different heights and layouts, so choosing the right beam angle is key to achieving even, glare-free lighting. A 60° narrow beam suits high mounting heights (35–50 ft) by concentrating lux for tall workshops and hangars. A 90° medium beam is ideal for most warehouses because it balances vertical and horizontal light. For retail areas, sports halls, or open spaces, a 120° wide beam spreads light broadly and reduces shadows. Matching the beam angle to the space helps designers meet EN 12464-1 and IES requirements with fewer fixtures and better visibility.

Aisle Optics for Warehousing

Tall storage racks need lighting that delivers both floor and vertical visibility. Aisle-specific optics—such as 30°×70° or 60°×100°—direct light forward along narrow shelving rows, minimizing wasted lumens and improving picker accuracy. This enhances uniformity, reduces dark gaps between racks, and increases forklift safety. Standard 90° or 120° beams spread light too widely for aisles, so engineered aisle optics reduce fixture count while achieving better lighting performance. These specialized beam patterns align with IES LM-79 photometric distributions used in professional high bay warehouse lighting designs.

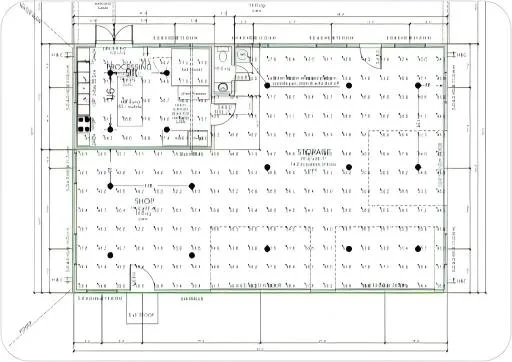

Mounting, Spacing, and Height Considerations

Mounting Options for High-Bay Lighting

Led high bay lighting fixtures support multiple mounting methods to match different ceiling structures and workflow layouts. Hook mounts and chain mounts are popular for warehouses due to fast installation and flexibility during layout changes. Pendant mounts and ceiling mounts offer greater stability for production floors and areas with vibrations. For outdoor yards or high-ceiling logistics hubs, high-mast brackets allow fixtures to be aimed precisely to achieve target lux levels. Choosing the correct mounting method improves light uniformity, reduces shadowing, and ensures compliance with EN 12464-1 and IES industrial lighting guidelines.

Spacing Rules for high bay leds

Proper spacing is essential to achieve consistent lux levels and avoid bright–dark patterns across the floor. A common engineering rule is: fixture spacing ≈ mounting height. For example, at a 30-ft mounting height, optimal spacing usually falls between 28–32 ft, depending on beam angle and ceiling reflectance. Narrow beams require tighter spacing, while wide beams cover larger areas. Correct spacing helps maintain uniformity ratios (U₀ ≥ 0.4, EN 12464-1) and prevents wasted lumens—resulting in lower energy usage and fewer fixtures needed to meet target illumination levels.

Avoiding Shadow Zones in Racked Facilities

Warehouses with tall racking systems are prone to dark aisles and shadow pockets if fixtures are not designed with directional optics. To prevent this, lighting layouts should use aisle-specific beam patterns, linear high-bay fixtures, or cross-lighting strategies that push illumination along the shelving rows. These optical solutions increase vertical lux, improve barcode readability, and reduce forklift risks. Eliminating shadow zones significantly improves picking accuracy, worker safety, and compliance with EN 12464-1 recommendations for vertical illumination in storage spaces.

Color Temperature & CRI — Visual Comfort Matters

Best Color Temperatures for Industrial Facilities

Color temperature directly affects visibility, comfort, and task accuracy in industrial environments. 5000K lighting provides crisp, daylight-like brightness, making it ideal for warehouses, manufacturing floors, and logistics centers where high visual clarity is needed. 4000K offers a more balanced and comfortable tone, commonly used in retail areas, packaging zones, and commercial spaces where workers spend long hours under the lights. Selecting the right color temperature helps reduce visual fatigue, improves productivity, and supports consistent color perception—important for safety, barcode scanning, and equipment operation in modern industrial facilities.

CRI Requirements for Industrial and Commercial Spaces

The Color Rendering Index (CRI) affects how accurately workers can see colors, labels, and fine details—making it a key quality factor in industrial led high bay lighting. CRI 70–80 is suitable for heavy industry, warehouses, and general work areas where basic visibility is sufficient. For more detailed tasks, such as inspection zones, packaging lines, quality control stations, and retail displays, CRI 80–90 is recommended to ensure accurate color judgment and clear label reading. High-CRI lighting not only improves task accuracy but also reduces mistakes, enhances safety, and provides better visual comfort. This leads to higher overall efficiency in manufacturing and commercial environments.

IP, IK, and Environmental Protection

Industrial environments can be harsh, so selecting the correct protection level is essential for long-term reliability. industrial high bay lights should offer IP65 or IP66 ratings to ensure complete dust protection and resistance to water jets. For mechanical durability, IK08 or IK10 impact resistance prevents damage from tools, forklifts, or accidental impacts. In coastal, chemical, or food-grade facilities, anti-corrosion coatings are necessary to prevent metal degradation over time. Areas with high humidity—such as car washes, food processing plants, or wash-down zones—benefit from vapor-tight housings that keep moisture out of internal components.

Smart Controls — The New Standard in industrial high bay lighting

Motion Sensors

Modern high bay led light bulbs can integrate several types of motion sensors, including microwave sensors, PIR sensors, and aisle-oriented detection modules. These smart controls automatically adjust lighting based on real-time occupancy, significantly reducing unnecessary operating hours in low-traffic warehouse zones, loading docks, night-shift production lines, and cold-storage environments. Depending on the facility layout and workflow patterns, motion-sensor control can deliver 20–60% additional energy savings, making it one of the most effective upgrades for industrial energy management.

Daylight Harvesting Sensors

Daylight harvesting sensors automatically dim high bay lights in areas exposed to natural light, such as spaces with skylights, open dock doors, or large translucent wall panels. By dynamically adjusting output based on real-time daylight levels, these sensors help maintain consistent illumination while minimizing energy waste. This approach is especially effective in logistics centers and distribution warehouses, where natural light varies throughout the day.

Dimmable Drivers (0–10V / DALI / PWM)

Dimmable LED drivers—using 0–10V, DALI, or PWM protocols—enable smooth integration with smart building systems, industrial automation platforms, and centralized facility management software. These drivers support adaptive brightness control, scheduling, and zone-based lighting strategies, allowing operators to optimize energy usage without compromising visibility or safety. They are essential components in modern Industry 4.0-ready lighting systems.

Photometric Planning — The Only Way to Get Lighting Right

Professional facilities require photometric calculations (IES files + lighting simulation).

This ensures compliance with illumination standards, for example:

Required Lux Levels for Professional Facilities

Professional facilities must meet specific lux requirements to ensure safety, visibility, and work accuracy. Warehouses typically need 200–300 lux, manufacturing lines require 300–500 lux, and precision assembly areas may need 500–800 lux to support fine-detail tasks. Sports halls and gymnasiums usually fall in the 300–750 lux range to maintain safe movement and visual comfort. These values come from EN 12464-1 and IES lighting standards and form the foundation for every lighting layout.

Why Photometric Calculations Are Essential

Photometric design—using IES files and lighting simulation software—is essential because it predicts how light will perform before installation. Simulations help verify uniformity, eliminate dark spots, and control glare, ensuring the lighting meets required standards. They also optimize the fixture count, preventing both under-lighting and unnecessary over-lighting. This process ensures the final installation delivers consistent, safe, and efficient illumination throughout the facility.

Total Cost of Ownership (TCO) and ROI

led high bay warehouse lighting provides long-term financial value.

Savings come from:

Reduced Energy Bills

Switching from HID to LED hi bay lighting can reduce energy consumption by 60–70%, because LEDs convert far more electricity into visible light instead of heat. This results in immediate and long-term savings for warehouses, factories, and logistics centers that operate lights for long hours. Lower power demand also reduces strain on electrical infrastructure, helping facilities cut utility costs month after month.

Lower Maintenance Costs

LED high bay fixtures last 50,000–100,000 hours, meaning facilities avoid frequent lamp replacements, ballast failures, and the need to rent lift trucks for high-ceiling maintenance. Fewer maintenance cycles also reduce workplace interruptions and safety risks related to accessing elevated fixtures. This long lifecycle makes LED upgrades one of the most cost-effective improvements in industrial lighting.

Productivity & Safety Improvements

Better lighting improves visibility, reduces shadows, and enhances color recognition. This leads to fewer operational errors, higher picking accuracy, and fewer workplace incidents. Uniform, well-designed lighting also reduces visual fatigue and supports safer forklift operations—directly improving productivity and overall safety in industrial environments.

Utility Rebates (Region-Dependent)

In many countries and regions, utility companies offer rebates or incentives for installing high-efficiency led high bay light fixture. These programs help offset the upfront cost of upgrading from HID to LED, speeding up payback periods and improving ROI. Eligibility varies by location, but facilities using DLC-listed or ENERGY STAR-qualified products often qualify for significant savings.

Applications of industrial high bay led lighting

led bay lighting is widely used across many commercial and industrial environments, including warehouses, distribution centers, manufacturing plants, automotive factories, cold storage facilities, and food-processing areas. It is also essential for supermarkets, big-box retail stores, gymnasiums, sports arenas, exhibition halls, logistics hubs, and large airport hangars, where powerful and uniform illumination is required for safety and productivity. For facility upgrades, you can explore our led street light, led flood light, highbay led light, and led canopy light options.

How to Choose the best high bay led lights (Step-By-Step)

Selecting the right hi bay led lighting follows a clear engineering workflow. First, define the space by confirming its dimensions, ceiling height, and whether the layout is open or aisle-based. Next, choose the appropriate fixture style—UFO or linear—along with the required environmental protection such as IP or IK ratings. Then select the proper lumen output based on mounting height and the target lux level. After that, choose the right optics, whether a standard beam angle or aisle-specific distribution. Color temperature (CCT) and CRI should be matched to the visual tasks and safety requirements of the facility. Smart controls such as motion sensors, daylight harvesting, and dimmable drivers can then be added to reduce energy use. Once the product selection is made, confirm compliance with CE, UL, DLC, or local energy regulations. Finally, request a photometric simulation to ensure the proposed layout achieves the correct lux, uniformity, and coverage in real-world conditions.

Conclusion — LED High Bay Lighting Is Now an Engineering System, Not Just a Light

Modern high bay light fixture is no longer defined by wattage or simple brightness. It is a complete engineering system that integrates optical design, smart controls, environmental protection, photometric science, and long-term operational efficiency. In industrial and commercial environments, the quality of high bay lighting directly influences worker safety, productivity, facility uptime, energy cost, and overall ROI. To achieve reliable, high-performance results, facilities should choose high bay systems engineered specifically for their application—supported by accurate photometric design, high-quality components, and a proven B2B lighting manufacturer. Explore our highbay LED light, LED street light, LED flood light, solar LED street light, and LED canopy light solutions for professional-grade upgrades.